Chemical engineers use EXAKT three roll mills to improve penetration values and reduce noise in grease and lubrication formulations. Precise, compact, and efficient, these mills are among the most user-friendly devices in the industry. Learn more at EXAKTDispersion.com

From the food industry to nanotechnology, EXAKT three roll mills are used in a wide variety of industrial and research applications. No matter which paste must be processed, the EXAKT three roll mills can break open all kinds of agglomerates. This creates substances of the greatest fineness and quality.

- Adhesives: conductive, filled, underfills

- Colors: inks, coatings paints

- Cosmetics: lipsticks, eyeliner, makeup

- Dental: gels, pastes, restorative materials

- Electronics: flux, metal or carbon pastes

- Grease and lubrication

- Nano Technologies: graphene, CNT, ceramics

Make a great mill even better

- Add another layer of safety

- Attaches fast – no tools needed

- Save $$ on costly repairs

- Keep more of your spatulas

Designed for EXAKT 50 I use only.

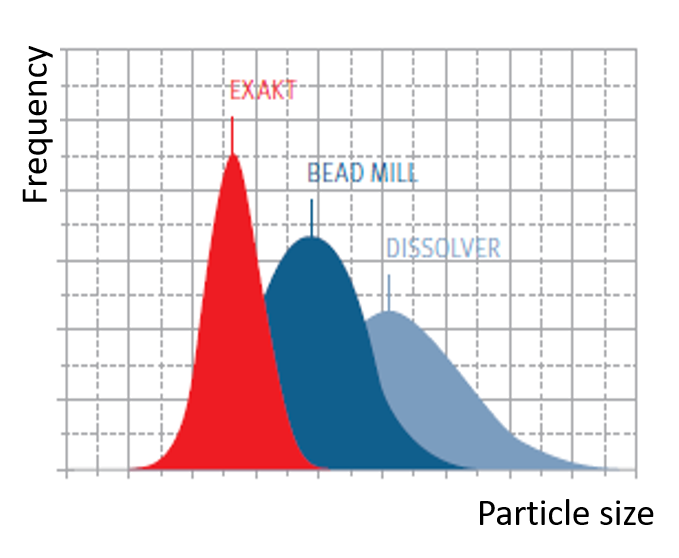

EXAKT three roll mills deliver results which are consistent and reproducible.

- Process materials accurately and dependably, including Nano particles

- Narrowest particle distribution

- No separation

- Processing down to 5 ml, virtually loss free

- Minimal cleaning losses

- Durable mills mean low operating costs

Keep your mill performing as it should. Often times what you think is a problem with the mill is really just a worn-out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months.

For quick ordering call 800-866-7172. Or email exaktorders@exaktusa.com.

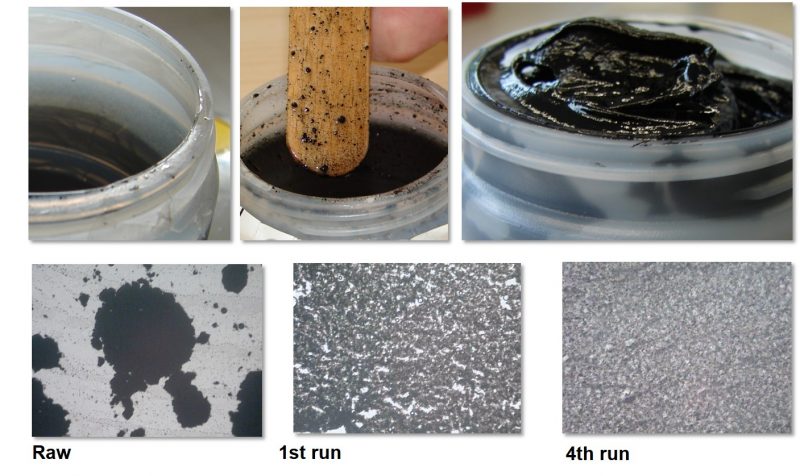

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include:

- Disperse the difficult – tangled CNT, especially in viscous pastes such as Epoxy and Silicone.

- Exfoliate graphite-based materials without destroying the plate-like structure.

- Control the level of dispersion.

EXAKT’s electronic models (80E Plus, and 120E) give the most precise control and repeatability.

Whether it’s for research or production, learn more by calling or emailing our three roll mill experts.

800-866-7172 | info@exaktusa.com

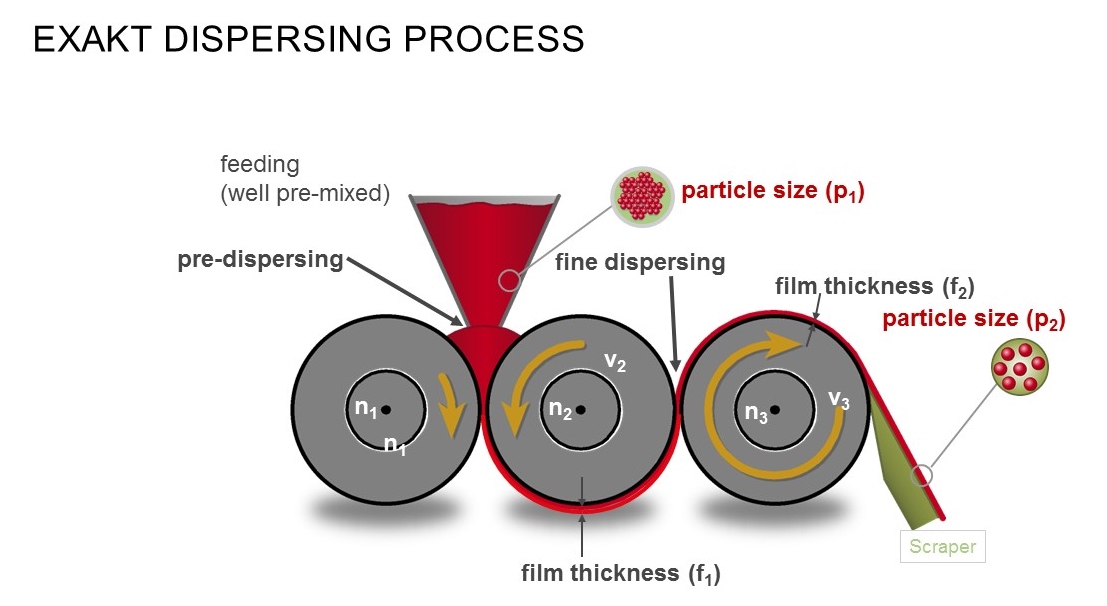

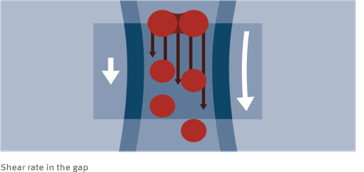

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones.

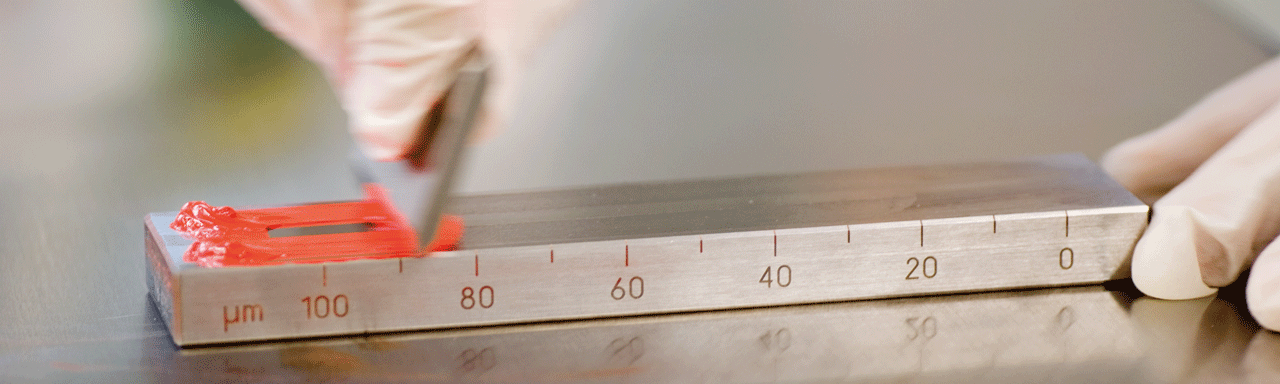

- The shear rate between the rollers is the decisive factor for the process.

- This is determined by the roller spacing and the circumferential speed.

- Agglomerates and powder clumps are broken up and homogenized.

- The more controlled the energy input, the more precise the processing.

Come talk to the experts and see the coolest three roll mill on the market –booth# 731.

Wed. Oct. 2nd – 10 AM to 5 PM

Thu. Oct. 3rd – 10 AM to 3 PM

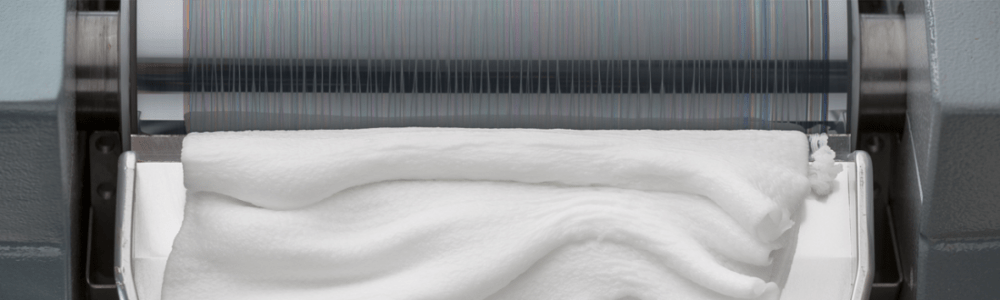

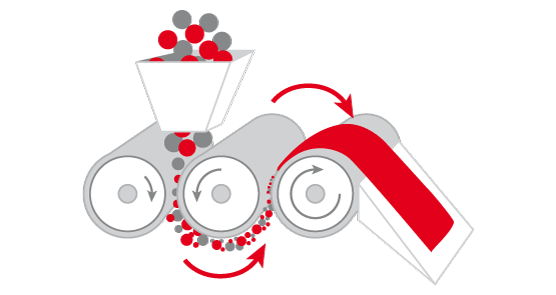

A three roll mill utilizes high shear force to disperse agglomerates, and homogenize viscous materials.

Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other.

The product is pulled through the gaps between the rollers. Agglomerates and powder clumps are broken up and homogenized.

Because precision matters.

Experience – More than 60 years in dispersion, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

Recent Comments