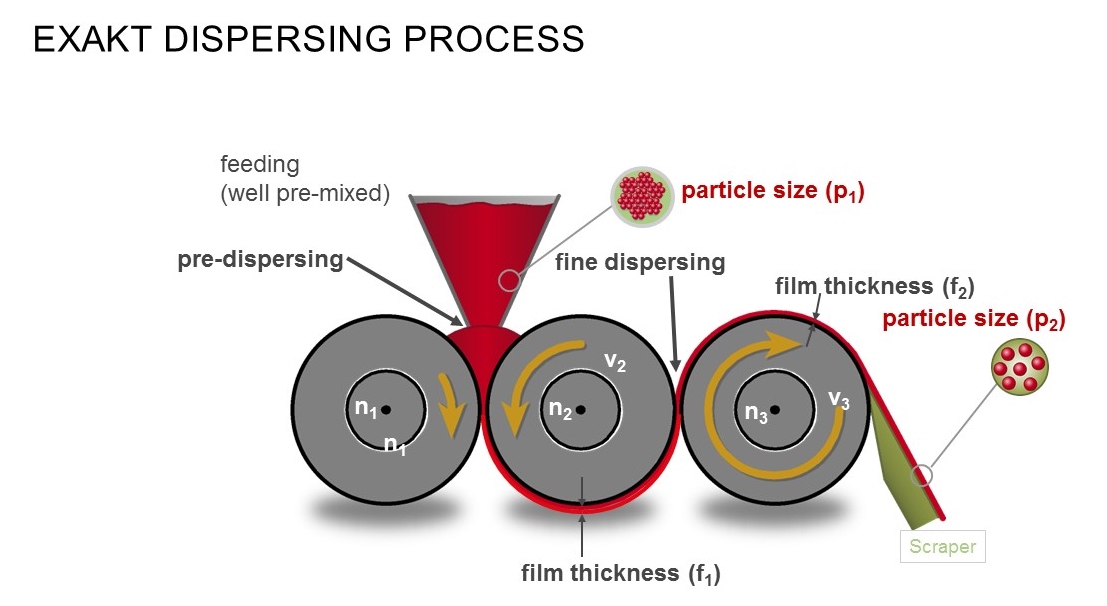

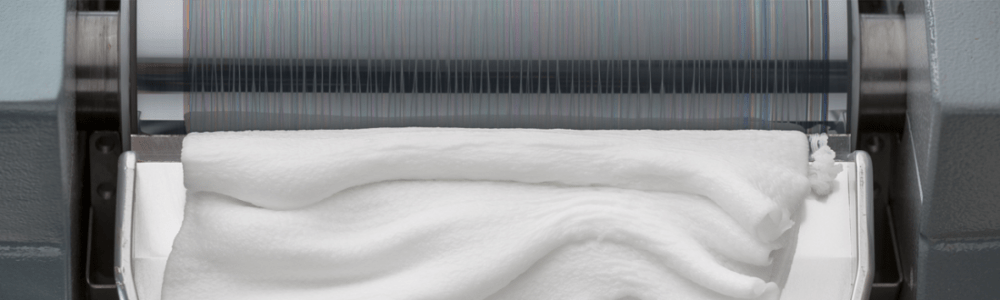

Add another layer of safety to your mill with this cleaning guard. Only compatible with the EXAKT 50 I. Order by calling 800-866-7172. Or email: EXAKTorders@exaktusa.com.

Whether you need replacement parts, repairs, or advice, EXAKT has factory-trained technicians and expert technical support to help you. We’ll make sure your equipment works the way it should.

Don’t forget to check out the Pathology Saw Resources page where you can watch and learn from videos designed to improve your experience with the saw.

Diamond Band – Special characteristics:

Diamond Band – Special characteristics:

Recent Comments