Designed For The Pathology Laboratory

Problem: Labs are using equipment originally designed to cut wood, stained glass, and even butchered meat. This has led to poor quality samples and extremely dangerous working conditions. Solution: EXAKT’s 312 Pathology Saw was specifically designed for the path lab after years of experience and cooperation with hospitals and universities. Results: High-quality gross samples with […]

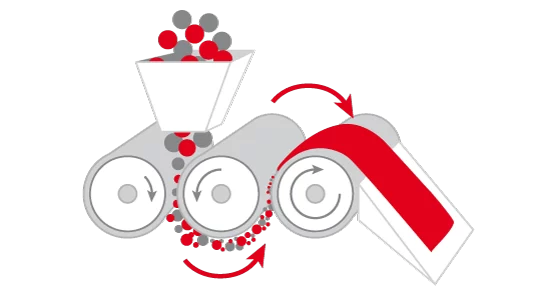

What does a three roll mill do?

A three roll mill utilizes high shear force to disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The product is pulled through the gaps between the rollers. Agglomerates and powder clumps are broken up and homogenized. […]