How to Use a Whetstone With EXAKT Pathology Saws

The whetstone is used to clean debris from the cutting band. This improves the performance of the cutting band. It’s important to note that the whetstone does NOT sharpen the cutting band.

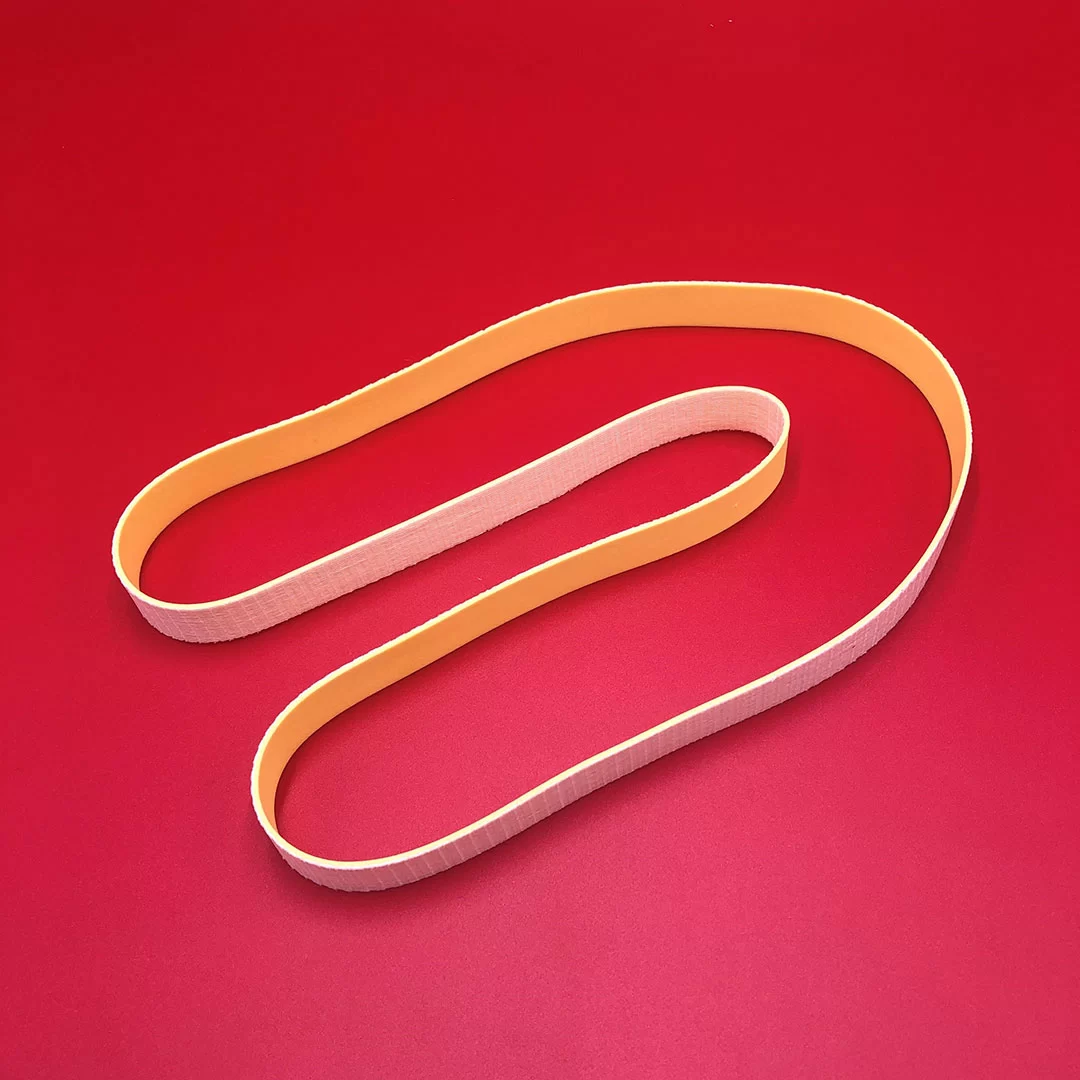

EXAKT Pathology Saws: Is It Time To Replace the Yellow Bands?

EXAKT’s Pathology Saw last a long time, and a little preventative maintenance will add even more years of reliable performance. We recommend replacing the yellow bands on your 312 Pathology Saw annually. The yellow bands keep the diamond band riding evenly on the pulleys. This can help improve performance and extend the life of your […]

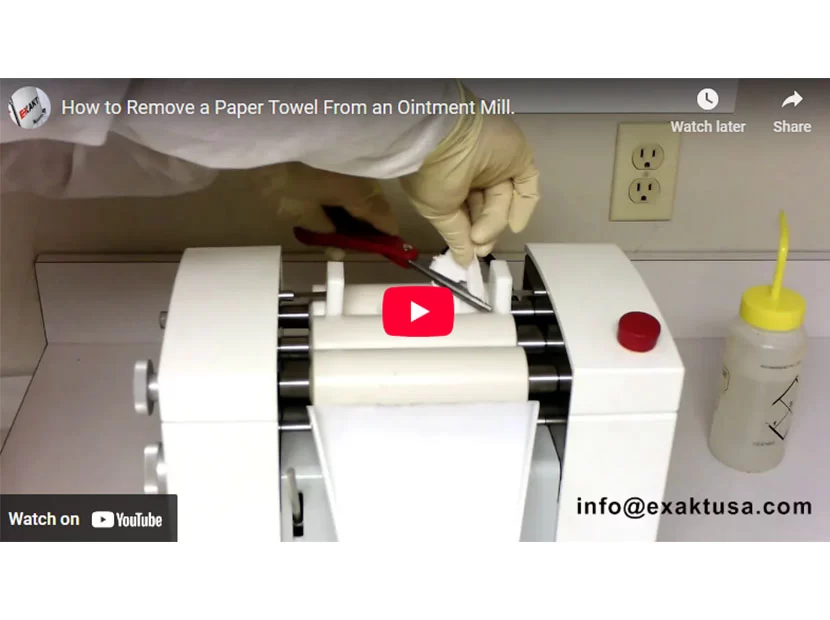

Video: How to Remove a Paper Towel in Your Ointment Mill

If your pharmacy is running back-to-back ointments and needs to clean its mills quickly. Instead of turning the machine off and turning the rollers with the hand wheel, they leave the machine running while wiping it clean. Not only is this unsafe for the technician, but it also risks damaging the mill. If something too […]