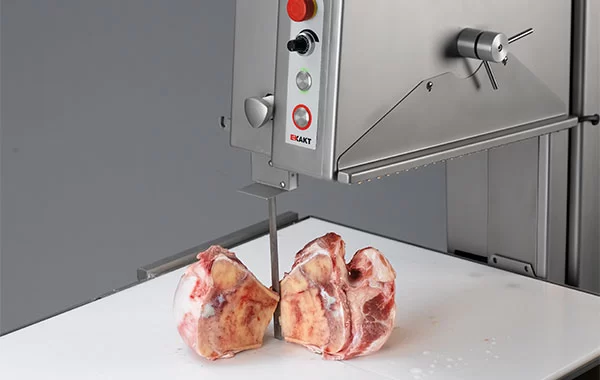

Precision and Safety in Grossing

EXAKT’s 312 Pathology Saw: Precision and Safety in Grossing When it comes to pathology, the EXAKT 312 Pathology Saw is a game-changer, offering exceptional performance for grossing tissue and bone samples. Here’s why: Unmatched Safety The EXAKT 312 is designed with safety in mind. Its exclusive diamond band grinds rather than cuts, virtually eliminating the […]

How EXAKT Three Roll Mills Create Better Ceramic Products

EXAKT three-roll mills contribute to the creation of better ceramic products through several key mechanisms: Uniform Dispersion: By effectively breaking down agglomerates and distributing ceramic powders and additives uniformly throughout the matrix, EXAKT three-roll mills ensure homogeneity in ceramic formulations. This leads to consistent material properties, such as mechanical strength, thermal stability, and chemical resistance, […]