7 Reasons to Choose the EXAKT 80E Plus Three Roll Mill

The 80E PLUS three roll mill delivers faster-dispersing results with real-time process analysis. By combining high-precision mechanical design with a state-of-the-art electronic control system, EXAKT has created the new standard for three roll mill technology. Users will have more information than ever before, and the ability to make adjustments on the go. Safe operation mode […]

5 Reasons to Choose EXAKT Ointment Mills

Because precision matters. EXAKT produces the most precise, safe, and user-friendly machines in their respective industries. These products are an investment meant to last. The “Made in Germany” stamp you see on each of our machines embodies the meticulous attention to detail and pride in workmanship. Our equipment is something special, and we want you […]

How to Improve the Performance of Your Pathology Saw

Replacing key parts will extend the life of your saw and improve its performance. The single best way to improve performance is to make your cutting band is replaced annually. For frequent users, replace the cutting band every six months. Whether you need replacement parts, repairs, or advice, EXAKT has factory-trained technicians and expert technical […]

5 Reasons to Choose EXAKT Cutting & Grinding Systems

Because precision matters. Experience – More than 30 years of thin sectioning experience and over 2,800 units in use around the world. Expertise – Leverage our 30 years of experience for your specific application. Service – Our factory-trained technicians are available to help repair and extend the life of your equipment. Products – Our products […]

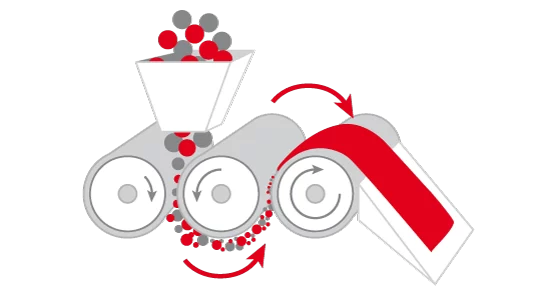

4 Advantages Using Three Roll Mills

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the decisive factor for the process. This is determined by the roller spacing and the circumferential speed. Agglomerates and powder clumps are broken up and homogenized. […]

EXAKT 50I Tune-Up

Prevent Downtime, Improve Performance EXAKT’s preventative maintenance program extends the life of your three roll mill and reduces downtime. EXAKT mills last a long time, and a little preventative maintenance will add even more years of reliable performance. New mill performance without the new mill cost Clean and check roller eccentricity for variance Calibrate rollers to […]

EXAKT Pathology Saws Reduce Aerosolized Formaldehyde

EXAKT’s water-cooled pathology saw can reduce the amount of aerosolized formaldehyde As hospitals and other pathology facilities process tissue samples in formaldehyde solution, it produces aerosolized formaldehyde (HCHO) in the air during the cutting process of the tissue samples. This research measures the level of formaldehyde produced during the processing of the sample (before cutting […]

Get Ointments with Softer Consistency

Research shows EXAKT ointment mills produce ointments with softer consistency and lower flow limits than those produced with EMPs (electronic mortar & pestle), most likely due to the significant temperature increase of ointments processed with EMPs. Make sure your customers get the most effective and elegant topicals by using an EXAKT ointment mill.

EXAKT Saws Easily Cut Metal Implants

The EXAKT 312 Pathology Saw can easily cut metal implants or screws that may be encountered during the grossing process, without destroying the sample. Even very small specimens can be cut safely and precisely! Learn more. Request a quote.

How often should I replace the guides and scraper on my mill

Keep your mill performing at a high level. Often times what you think is a problem with the mill is really just a worn-out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering, go to the EXAKT parts store.