EXAKT Pathology Saw Safety Features

Achieve unparalleled safety and precision with the EXAKT Pathology Saws Our exclusive Diamond Blade doesn’t cut – it grinds with extreme precision. There’s no immediate risk of injury if the band is accidentally touched: a first for occupational safety. Unlike machines made for butchering, wood, and glass cutting, the 312 is designed specifically for the […]

EXAKT Three Roll Mills for Nanocarbons

Nanocarbons, especially carbon nanotubes or graphenes, are the basis of a variety of new materials and products, e.g. for modern lightweight construction, for solar cells based on fullerenes, or flame arresters in foams. EXAKT Three Roll Mills are crucially important in the research, development, and production of this versatile material group. They enable high-precision dispersion […]

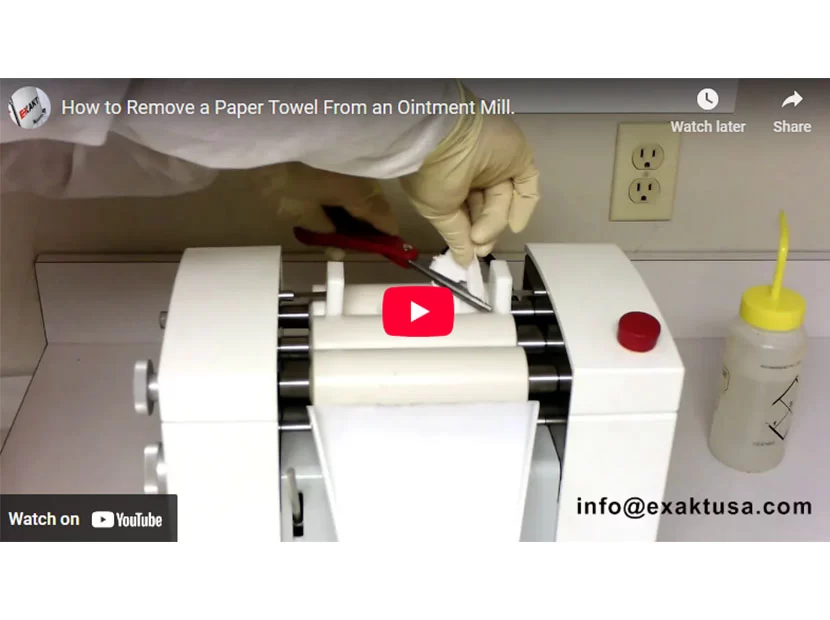

It Makes Cleaning Three Roll Mills Safe and Easy

Add another layer of safety to your mill with this cleaning guard. The cleaning bar keeps paper towels from getting stuck in the nip. For use with the EC Plus and 50I. Order online here. Or you can email exaktorders@exaktusa.com. To see more EXAKT three roll mill videos, click here.

How to Attach the Cutting Band on the EXAKT Pathology Saw

Attaching the cutting band on the EXAKT pathology saws can be done without tools, which makes it really easy.

Schedule a Virtual Pathology Saw Demo

Brochures and spec sheets are nice, but sometimes you have to see it live! Schedule a virtual demo to see EXAKT’s pathology saw in action. Learn about the safety features Get your questions answered Invite your colleagues to join Compare 302 vs 312 models See how easy it is to use and clean Schedule your demo! […]

5 Special Highlights: EXAKT’s Classic 50 Ointment Mill

With more than 30,000 units installed around the world, the EXAKT Classic 50 is the best-known and most accepted pharmaceutical ointment mill. The Classic 50 ensures excellent results for topical, oral, and suppository applications. When preparing ointments and creams containing crystallized ingredients, the EXAKT 50 is superior to even highly advanced mixing technologies. Applications: suspension […]

How to Use a Whetstone With EXAKT Pathology Saws

The whetstone is used to clean debris from the cutting band. This improves the performance of the cutting band. It’s important to note that the whetstone does NOT sharpen the cutting band.

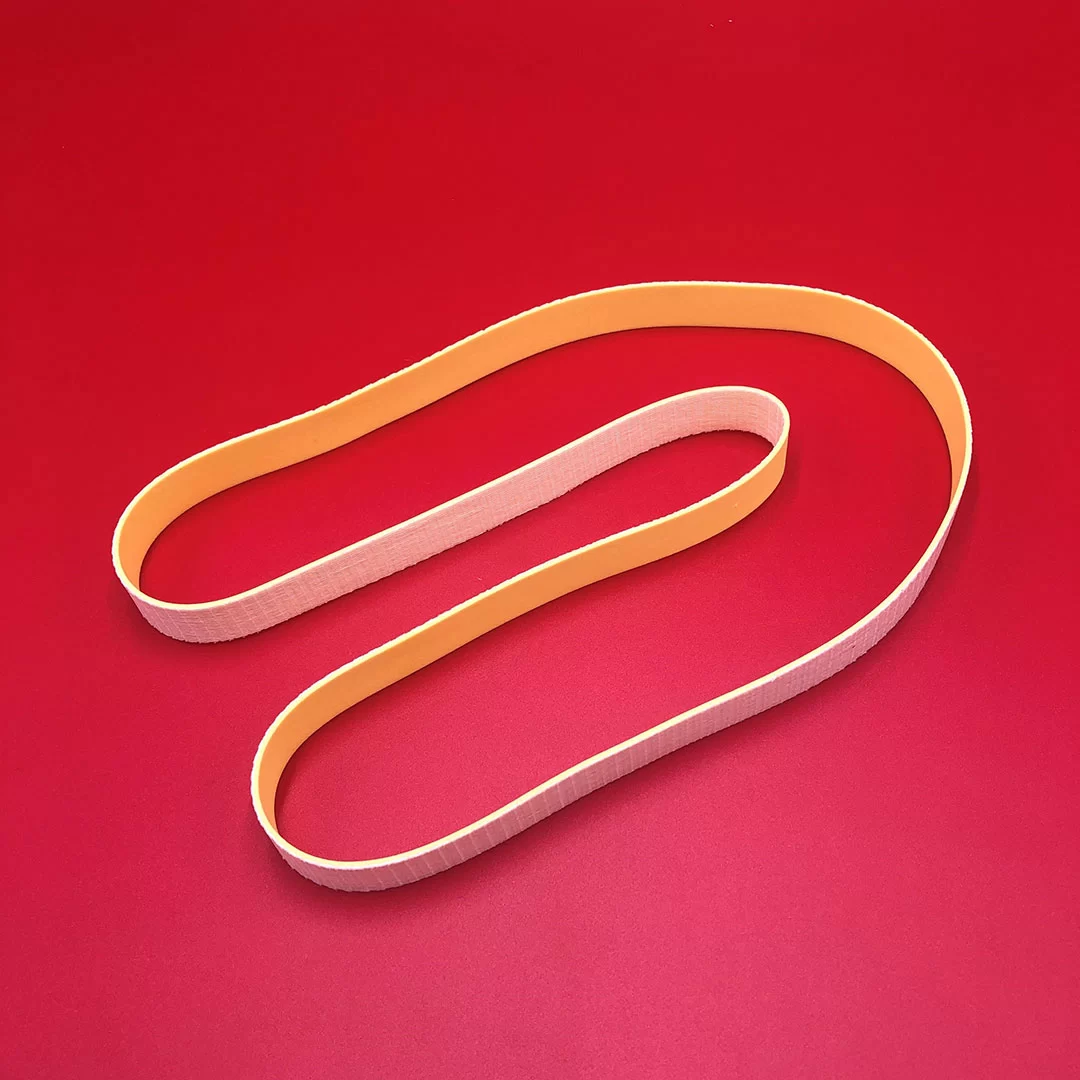

EXAKT Pathology Saws: Is It Time To Replace the Yellow Bands?

EXAKT’s Pathology Saw last a long time, and a little preventative maintenance will add even more years of reliable performance. We recommend replacing the yellow bands on your 312 Pathology Saw annually. The yellow bands keep the diamond band riding evenly on the pulleys. This can help improve performance and extend the life of your […]

Video: How to Remove a Paper Towel in Your Ointment Mill

If your pharmacy is running back-to-back ointments and needs to clean its mills quickly. Instead of turning the machine off and turning the rollers with the hand wheel, they leave the machine running while wiping it clean. Not only is this unsafe for the technician, but it also risks damaging the mill. If something too […]

Work Injuries Are Significant Burden on Hospitals

Work injuries can be a significant burden on hospitals and healthcare systems. Not only do they cause physical and emotional harm to the injured employee, but they also incur significant financial costs for the hospital. According to a study published in the American Journal of Industrial Medicine, the average cost of a work injury treated […]