How EXAKT Three Roll Mills Create Better Ceramic Products

EXAKT three-roll mills contribute to creating better ceramic products by ensuring uniform dispersion, controlled particle size reduction, and improved material integrity.

EXAKT three-roll mills contribute to creating better ceramic products by ensuring uniform dispersion, controlled particle size reduction, and improved material integrity.

The EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap.

EXAKT offeris Thermo Fisher Refrigerated Circulators alongside their renowned EXAKT Three Roll Mills.

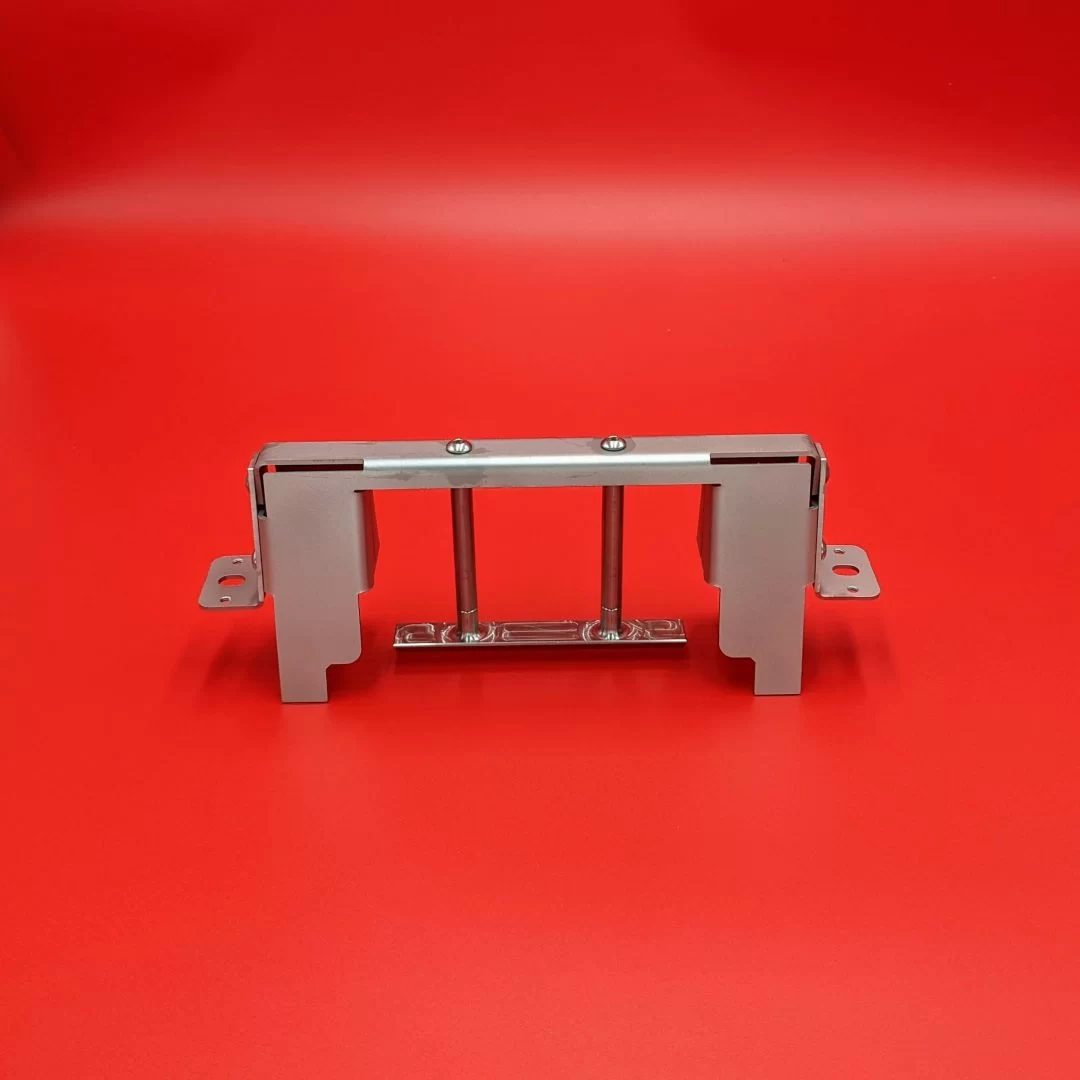

Add an extra layer of safety to your EXAKT 50 I three roll mill. Order here. Make a great mill even better Add another layer of safety Attaches fast – no tools needed Save $$ on costly repairs Keep more of your spatulas Designed for EXAKT 50I use only.

The 80E PLUS three roll mill delivers faster-dispersing results with real-time process analysis.

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones.

The EXAKT 80E PLUS sets the standard for demanding nanoparticle work, especially nanocarbons.

The EXAT 120S Plus consistently delivers excellent results at particle fineness down to 5 μm.

With a powerful motor and optional temperature control, the new 80S Plus was designed for processing a wide range of different materials.

Cosmetic chemists use EXAKT three roll mills to achieve greater color brilliance and fineness in medium to high viscosity substances.