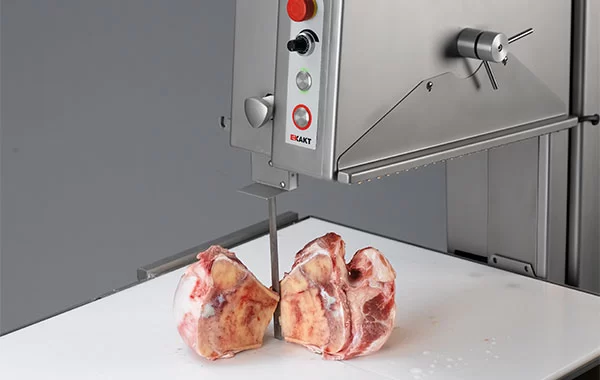

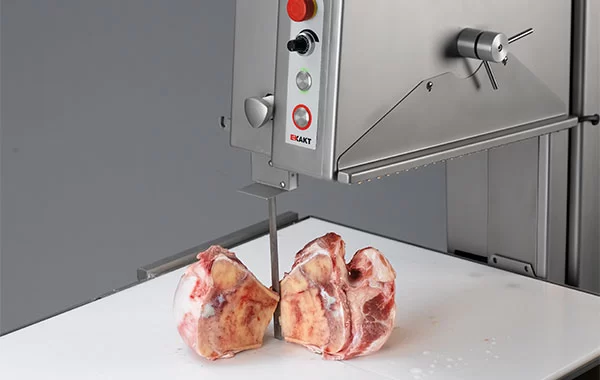

EXAKT’s 312 Diamond Band Pathology Saw

The EXAKT 312 Diamond Band Saw was developed to meet the special requirements of pathology and anatomy medicine.

The EXAKT 312 Diamond Band Saw was developed to meet the special requirements of pathology and anatomy medicine.

Processing bone and bone/soft tissue samples with a butcher’s saw produces poor results and handling is extremely dangerous. Even small diamond saws create artifact and limit the size of a sample that can be grossed. And neither can easily handle the surprise of an implanted device. The EXAKT Pathology Saw provides quick, precise sectioning of the sample. It delivers debris-free, undamaged surfaces for Surgical Pathology and cassette-size samples to enhance tissue processing for histology. It combines the highest level of safety with equally