How to Improve the Performance of Your Pathology Saw

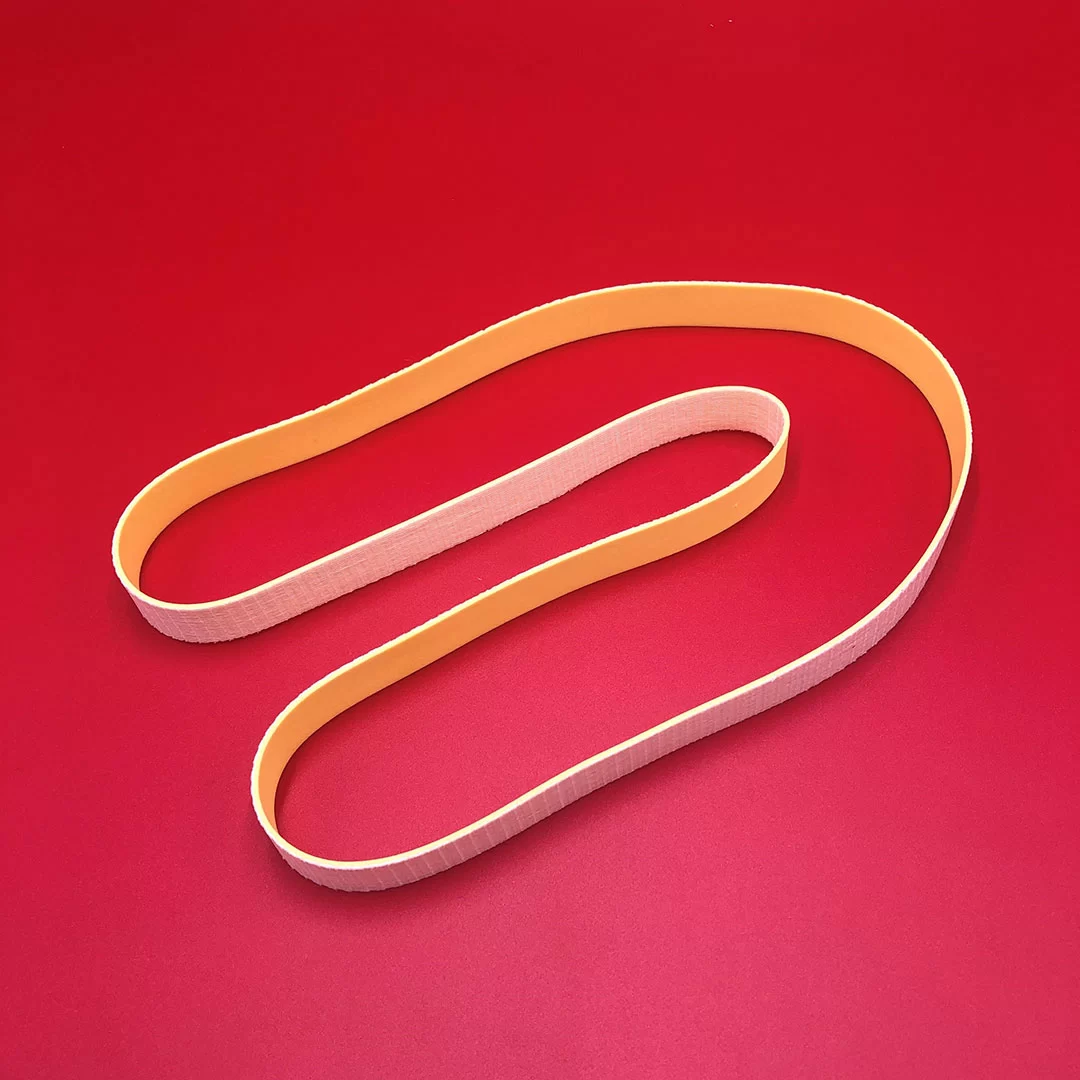

Replacing key parts will extend the life of your saw and improve its performance. The single best way to improve performance is to make your cutting band is replaced annually. For frequent users, replace the cutting band every six months. Whether you need replacement parts, repairs, or advice, EXAKT has factory-trained technicians and expert technical support to help you. We’ll make sure your equipment works the way it should. Don’t forget to check out the Pathology Saw Resources page where