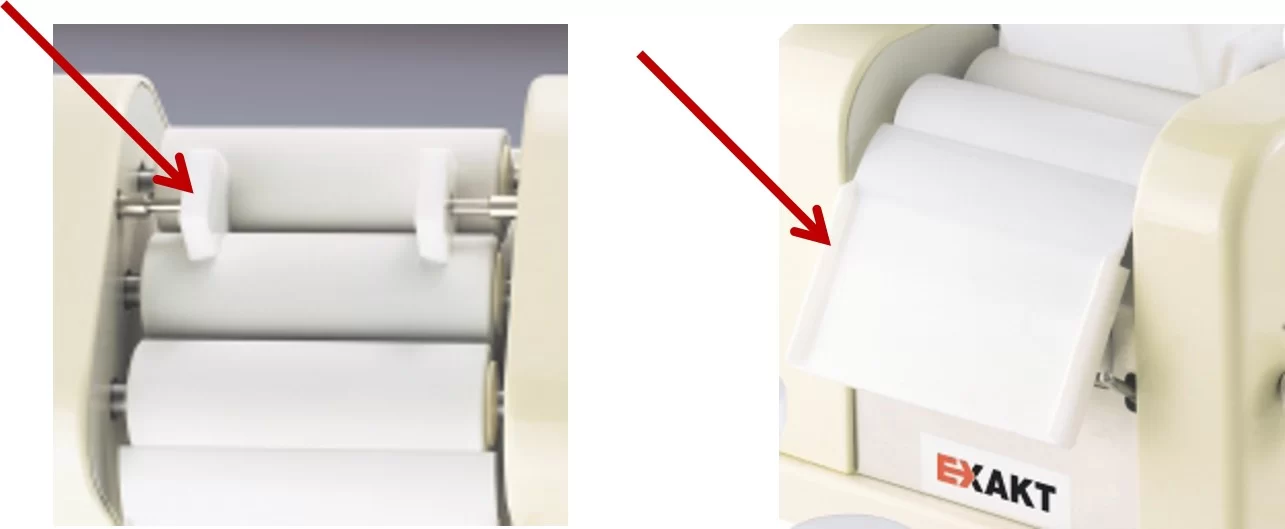

When to replace the guides and scraper on your ointment mill

Keep your mill performing at a high level. Often times what you think is a problem with the mill is really just a worn-out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering, go to the EXAKT parts store.

EXAKT Ointment Mills Get Results

EXAKT three ointment mills deliver results that are consistent and reproducible. A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with EXAKT ointment mills is better than those processed with electric mixing systems. The study highlighted the following conclusions: The particle size […]

EXAKT Launches the 50+ Rx 200 Ointment Mill

The new 50+ Rx 200 ointment mill offers significantly higher performance combined with a user-friendly design and operation. Key Features: • 70% More power with a 200 W motor • User-friendly touchpad • Variable speed control for precision • Easy one-hand gap adjustment • One-touch reverse•20 different gap settings for reproducibility • Emergency stop for […]

Get Ointments with Softer Consistency

Research shows EXAKT ointment mills produce ointments with softer consistency and lower flow limits than those produced with EMPs (electronic mortar & pestle), most likely due to the significant temperature increase of ointments processed with EMPs. Make sure your customers get the most effective and elegant topicals by using an EXAKT ointment mill.

How often should I replace the guides and scraper on my mill

Keep your mill performing at a high level. Often times what you think is a problem with the mill is really just a worn-out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering, go to the EXAKT parts store.

Elegant Ointments

EXAKT ointment mills produced ointments with softer consistency and lower flow limits than those produced with EMPs, most likely due to the significant temperature increase of ointments processed with EMPs (electronic mortar & pestle).

EXAKT 50I Three Roll Mill

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective in regard to fast cleaning, the avoidance of cross-contamination and downtimes due to changing the product. EXAKT 50 is indispensable for research, development, and training. […]

Time to replace your guides and scraper?

Keep your mill performing as it should. Often times what you think is a problem with the mill is really just a worn out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering call 800-866-7172. Or email exaktorders@exaktusa.com.

Time to replace your guides and scraper?

Keep your mill performing as it should. Often what you think is a problem with the mill is just a worn-out scraper and/or guides. If used regularly, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering: https://exaktusa.com/shop/. Or email: exaktorders@exaktusa.com.

Don’t Forget to Replace the Scraper and Guides

Often times what the operator thinks is a problem with the mill is really just a worn out scraper apron or flow guide. Rule of thumb: If you use the mill daily, replace the scraper and guides every 6 months. Need help? Call or email us today! 800-866-7172 inforx@exaktusa.com