3 Distinct Advantages Using EXAKT Ointment Mills

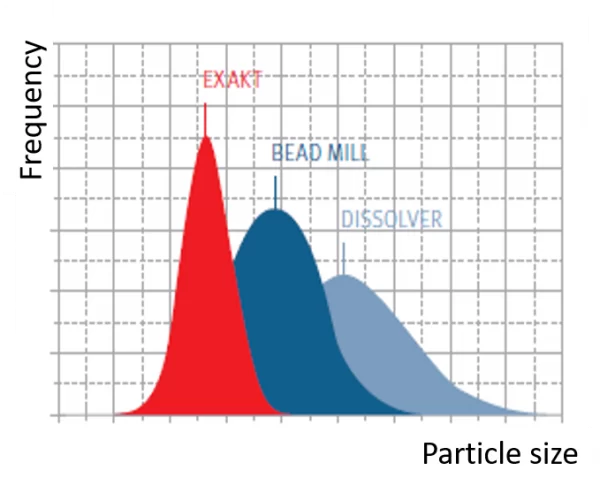

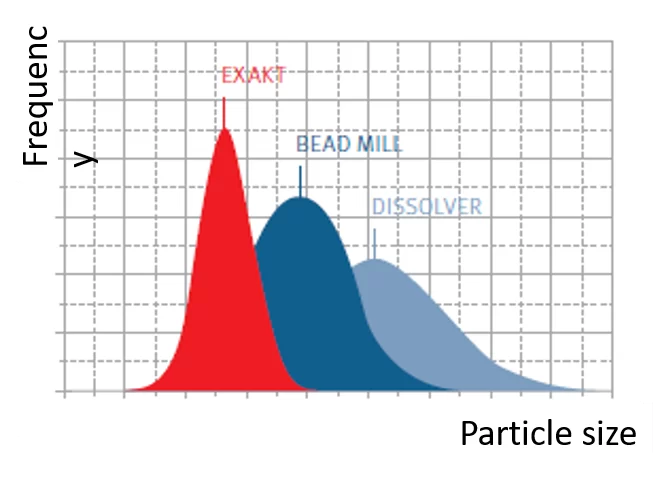

Ointment mills (three roll mills) offer a distinct advantage over other mixing techniques. Only the ointment mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. This is why no mixer can do what an ointment mill does. The shear rate between the rollers is the decisive […]

7 Reasons to Choose the EXAKT 80E Plus Three Roll Mill

The 80E PLUS three roll mill delivers faster-dispersing results with real-time process analysis. By combining high-precision mechanical design with a state-of-the-art electronic control system, EXAKT has created the new standard for three roll mill technology. Users will have more information than ever before, and the ability to make adjustments on the go. Safe operation mode […]

4 Advantages Using Three Roll Mills

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the decisive factor for the process. This is determined by the roller spacing and the circumferential speed. Agglomerates and powder clumps are broken up and homogenized. […]

Why Choose EXAKT Ointment Mills

Because precision matters. Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide. Expertise – Extensive knowledge of applications with a wide variety of materials. Service – Factory-trained technicians are available to help repair and extend the life of your equipment. Products – Machines are made for the customer with […]

The EXAKT 80S Plus

The new EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control and the choice of ceramic and metallic rollers, the new 80S Plus was designed for processing a wide range of different materials. This three roll mill works well […]

EXAKT 50I Three Roll Mill

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective in regard to fast cleaning, the avoidance of cross-contamination and downtimes due to changing the product. EXAKT 50 is indispensable for research, development, and training. […]

Three Roll Mill Applications

From the food industry to nanotechnology, EXAKT three roll mills are used in a wide variety of industrial and research applications. No matter which paste must be processed, the EXAKT three roll mills can break open all kinds of agglomerates. This creates substances of the greatest fineness and quality. Adhesives: conductive, filled, underfills Colors: inks, coatings paints […]

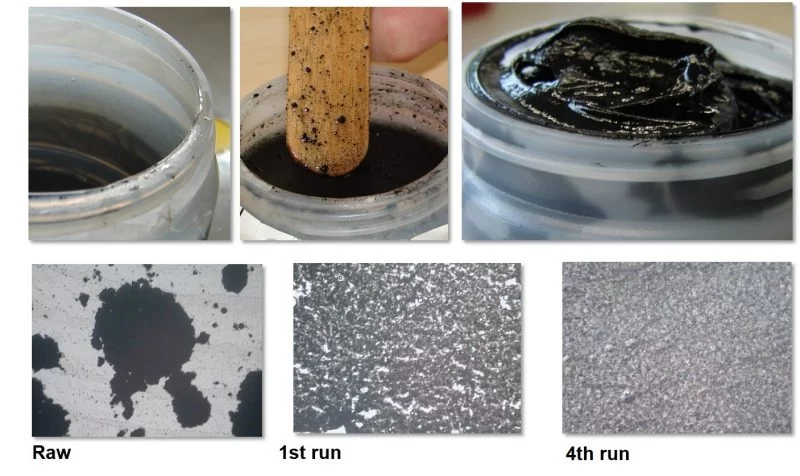

EXAKT Three Roll Mills for Carbon Applications

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include: Disperse the difficult – tangled CNT, especially in viscous pastes such as Epoxy and Silicone. Exfoliate graphite-based materials without destroying the plate-like structure. Control the level of dispersion. EXAKT’s electronic models (80E Plus, and 120E) give […]

Ointment Mill Advantages

Only the ointment mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the decisive factor for the process. This is determined by the roller spacing and the circumferential speed. Agglomerates and powder clumps are broken up and homogenized. […]

Three Roll Mill Advantages

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the decisive factor for the process. This is determined by the roller spacing and the circumferential speed. Agglomerates and powder clumps are broken up and homogenized. […]