EXAKT Launches the 50+ Rx 200 Ointment Mill

The new 50+ Rx 200 ointment mill offers significantly higher performance combined with a user-friendly design and operation. Key Features: • 70% More power with a 200 W motor • User-friendly touchpad • Variable speed control for precision • Easy one-hand gap adjustment • One-touch reverse•20 different gap settings for reproducibility • Emergency stop for […]

The EXAKT 80E Plus Three Roll Mill

The 80E PLUS three roll mill delivers faster-dispersing results with real-time process analysis. By combining high-precision mechanical design with a state-of-the-art electronic control system, EXAKT has created the new standard for three roll mill technology. Users will have more information than ever before, and the ability to make adjustments on the go. Safe operation mode […]

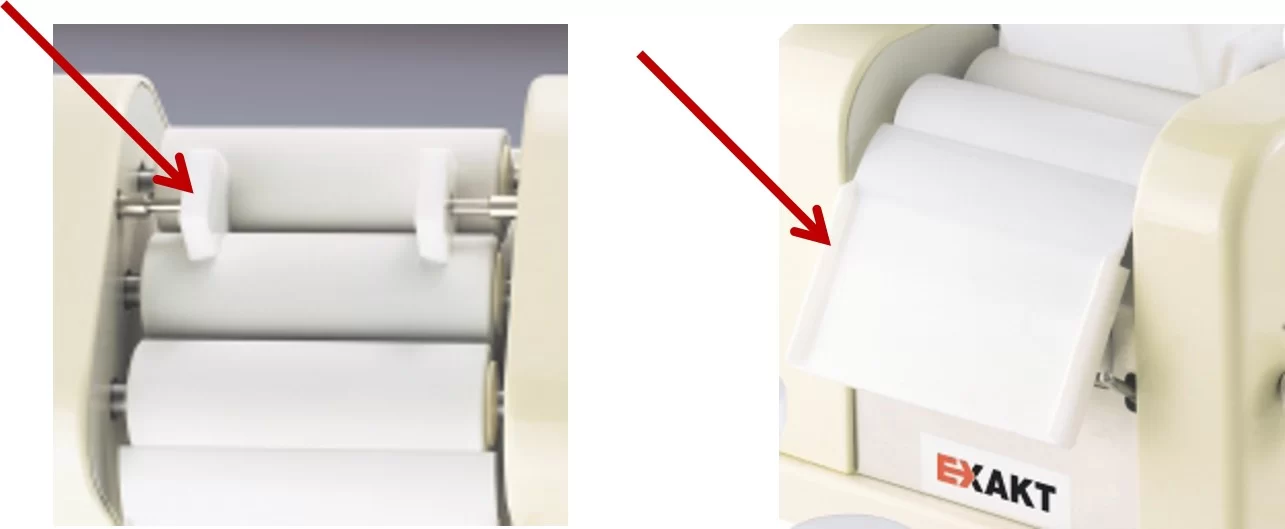

Don’t Forget to Replace the Scraper and Guides

Often times what the operator thinks is a problem with the mill is really just a worn out scraper apron or flow guide. Rule of thumb: If you use the mill daily, replace the scraper and guides every 6 months. Need help? Call or email us today! 800-866-7172 inforx@exaktusa.com

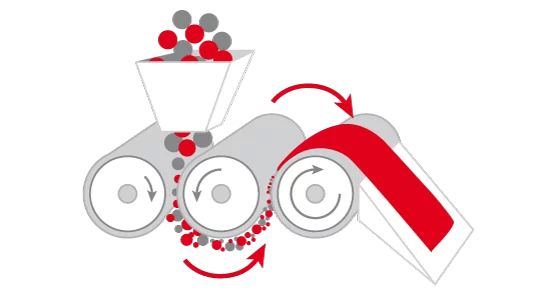

The Ointment Mill Process

An ointment mill utilizes high shear force to reduce particle sizes, disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The whole product is pulled through the gap between the rollers, resulting in a precise, controllable, and […]