Three Roll Mill Advantages

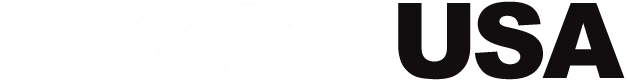

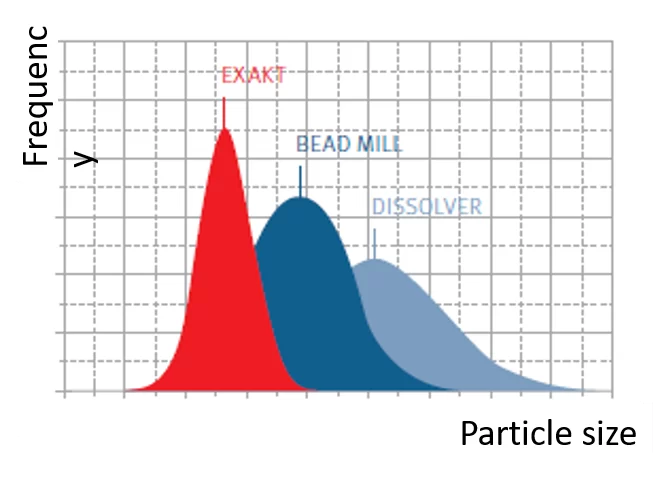

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the decisive factor for the process. This is determined by the roller spacing and the circumferential speed. Agglomerates and powder clumps are broken up and homogenized. […]

What does a three roll mill do?

A three roll mill utilizes high shear force to disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The product is pulled through the gaps between the rollers. Agglomerates and powder clumps are broken up and homogenized. […]

EXAKT Three Roll Mills for Grease and Lubrication

Chemical engineers use EXAKT three roll mills to improve penetration values and reduce noise in grease and lubrication formulations. Precise, compact, and efficient, these mills are among the most user-friendly devices in the industry. Learn more at EXAKTDispersion.com

Have you seen the new EXAKT 80E Plus?

Experience our most advanced three roll mill.

Improve the Performance of Your Ointment Mill.

Your Ointment Mill May Need a Tune-up EXAKT ointment mills rarely require repair, but sometimes a tune-up can help improve the performance of your machine and provide years of worry-free use. For smaller mills, we can turn your mill around the same day it’s received at our shop to minimize downtime. For larger mills, simply […]