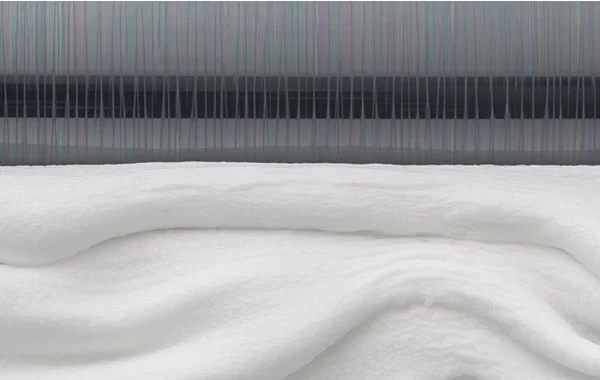

EXAKT Three Roll Mills for Cosmetics

Cosmetic chemists use EXAKT three roll mills to achieve greater color brilliance and fineness in medium to high viscosity substances. EXAKT mills are excellent for breaking open agglomerates and reducing particle sizes to the micron level. Precise, compact, and efficient, EXAKT three roll mills are among the most user-friendly devices in the cosmetic industry. Learn […]

Conventional Mixing vs. EXAKT Milling

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems. Particle size is smaller. Particle size distribution is narrow. Ointment stability is better. Temperatures do not increase significantly during processing. […]