Why Mixing Method Matters in Pharmaceutical Compounding

In pharmaceutical compounding, consistency, particle size, and homogeneity are not just quality markers—they directly affect patient outcomes. While conventional mixers remain common in pharmacies, they often fall short when working with high-viscosity ointments, suspensions, and creams.

EXAKT ointment mills are engineered specifically for pharmaceutical applications, offering controlled shear, reproducible results, and superior compound quality that mixers cannot match.

1. True Homogenization Through Controlled Shear

Unlike mixers that rely on bulk motion, EXAKT ointment mills use precision-adjustable rollers to apply controlled shear forces. This allows:

Uniform particle size reduction

Elimination of agglomerates

Consistent dispersion of APIs throughout the base

The result is a homogeneous compound with predictable performance and dosing accuracy.

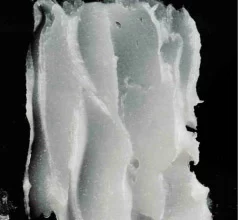

2. Softer, More Elegant Ointment Consistency

One of the most noticeable differences when switching from mixers to an EXAKT ointment mill is improved texture.

Because the milling process aligns particles rather than whipping air into the compound, pharmacies achieve:

Smoother mouthfeel and skin feel

Reduced grittiness

Improved patient acceptance and compliance

This is especially important for dermatological and pediatric preparations.

3. Superior Performance With High-Viscosity Formulations

Conventional mixers struggle with dense ointments, often requiring extended mixing times or repeated passes. EXAKT ointment mills are designed to handle high-viscosity and sticky formulations efficiently, reducing rework and operator fatigue.

4. Consistent, Repeatable Results Batch After Batch

Because roller gap settings are precisely adjustable and repeatable, EXAKT mills deliver process consistency across:

Different operators

Different batches

Different pharmacy locations

This repeatability supports quality assurance protocols and simplifies training.

5. Cleaner Processing and Less Product Loss

Mixers frequently trap material along vessel walls and blades. EXAKT ointment mills allow compounds to be processed directly on the rollers, minimizing waste and simplifying cleanup—an important advantage for expensive APIs.

Why Pharmacies Choose EXAKT

For decades, EXAKT has been trusted by pharmacies worldwide for one reason: results that mixers cannot replicate. From smoother ointments to more consistent dosing, EXAKT ointment mills help compounding pharmacies elevate both efficiency and patient care.

👉 Related content: [EXAKT Ointment Mills Product Overview]

👉 Also read: [How Roller Gap Settings Affect Compound Quality]

Learn More

Ready to elevate your compounding outcomes? Contact one of our distributors for the 50 Plus Pharma.

For larger mills, contact EXAKT directly to request a quote or arrange a demonstration.