When should you consider an additional mill?

Whether you already own an EXAKT ointment mill or a mill from another manufacturer, the EXAKT 50EC+ is the best choice when considering additional mills. The EXAKT 50EC+ is a modular ointment mill, designed with removable rollers for easy, efficient cleaning. With the purchase of an extra set of rollers, you can increase efficiency in your pharmacy by having […]

Smart Dispersion

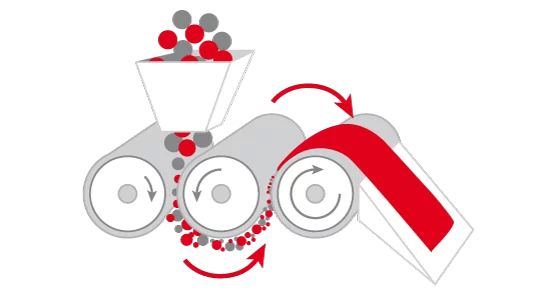

The Ointment Mill Process

An ointment mill utilizes high shear force to reduce particle sizes, disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The whole product is pulled through the gap between the rollers, resulting in a precise, controllable, and […]

EXAKT’s Tissue Preparation Process

Don’t take chances when handling rare or unique samples. Mistakes in the preparation process delay your work and can provide false results. That’s a risk you shouldn’t take. Trust the decades of experience with globally tried-and-tested thin section cutting technology from EXAKT. We guide you through the sample preparation process, which helps your unique research results. […]

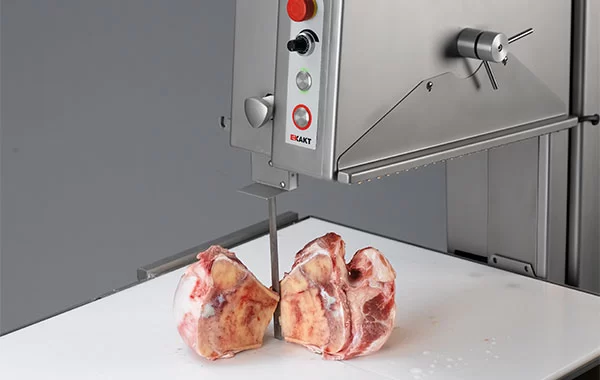

EXAKT’s 312 Diamond Band Pathology Saw

Designed for the Pathology Lab The EXAKT 312 Diamond Band Saw was developed to meet the special requirements of pathology and anatomy (human and veterinary) medicine. With the EXAKT 312, even the smallest cuts down to about 1 mm can be made freehand with almost no risk of cuts to the operator. Whether it’s soft tissue, bones or […]

Three Roll Mills for Cosmetics

Cosmetic Manufactures Use EXAKT Three Roll Mills For Brilliant Colors When it comes to color brilliance, color effects and high color intensity, EXAKT Three Roll Mills offer significant advantages. For example, the primary particles are not damaged during the processing of metallic and effect pigments. Optimal process control and reproducible quality are a matter of […]

How to Clean Your Ointment Mill

CLEANING YOUR EXAKT OINTMENT MILL For everyday cleaning between formulations, alcohol and a soft cloth or paper towel are the best things to use. Do NOT spray the alcohol on the rollers or pour the alcohol into the gap when the machine is running. Put the alcohol on a paper towel or cloth and hold […]

Thin Section Technology: Gently Cutting The Uncuttable

When conventional cutting processes reach their limits or the requirements on surface quality of the interface are very high, EXAKT diamond band saws like the 300, 310 (CL & CP), and 311 series are the solution to your problems. EXAKT diamond band saws are used on a daily basis around the world for thin sectioning. […]

Improve the Performance of Your Ointment Mill.

Your Ointment Mill May Need a Tune-up EXAKT ointment mills rarely require repair, but sometimes a tune-up can help improve the performance of your machine and provide years of worry-free use. For smaller mills, we can turn your mill around the same day it’s received at our shop to minimize downtime. For larger mills, simply […]

Your Three Roll Mill May Need a Tune-up

Has your three roll mill been serviced in the last two years? EXAKT three roll mills rarely require repair, but sometimes a tune-up can help improve the performance of your machine and provide years of worry-free use. For smaller mills, we can turn your mill around the same day it’s received to minimize down […]