Why Controlled Sheer Matters

Carbon nanotubes (CNTs) are among the most powerful functional additives in advanced materials engineering. With exceptional electrical conductivity, mechanical strength, and high aspect ratio, CNTs enable performance breakthroughs in:

Battery electrode slurries

Conductive inks and printed electronics

EMI shielding coatings

Structural conductive composites

However, realizing these properties depends on one critical factor:

Dispersion quality.

Poor dispersion destroys performance. Controlled shear unlocks it.

This is where the EXAKT Three Roll Mill becomes a strategic tool rather than just a mixing device.

Why Carbon Nanotube Dispersion Is So Challenging

CNTs do not arrive ready to perform.

They are typically supplied as tangled, highly agglomerated bundles held together by strong van der Waals forces. These forces cause nanotubes to:

Aggressively re-bundle

Resist wetting in most resin systems

Form conductive “dead zones”

Create rheology instability

If agglomerates are not properly broken down:

Electrical conductivity drops

Percolation thresholds increase

Mechanical reinforcement is reduced

Material costs rise due to overloading CNT content

In high-value systems, especially lithium-ion battery slurries or conductive coatings, improper dispersion directly affects performance, consistency, and margin.

CNT processing is not simply “mixing.”

It is microstructure engineering.

Controlled Shear vs. High-Energy Mixing

Many processors attempt CNT dispersion using bead mills, rotor-stator systems, or high-speed mixers. While these methods can reduce agglomerate size, they introduce risks:

Over-fragmentation of nanotubes

Excess heat generation

Media contamination

Limited repeatability

Broad particle size distribution

CNT performance depends on maintaining aspect ratio. Excessive impact energy can shorten nanotubes and disrupt conductive network formation.

A Three Roll Mill operates on a fundamentally different mechanical principle.

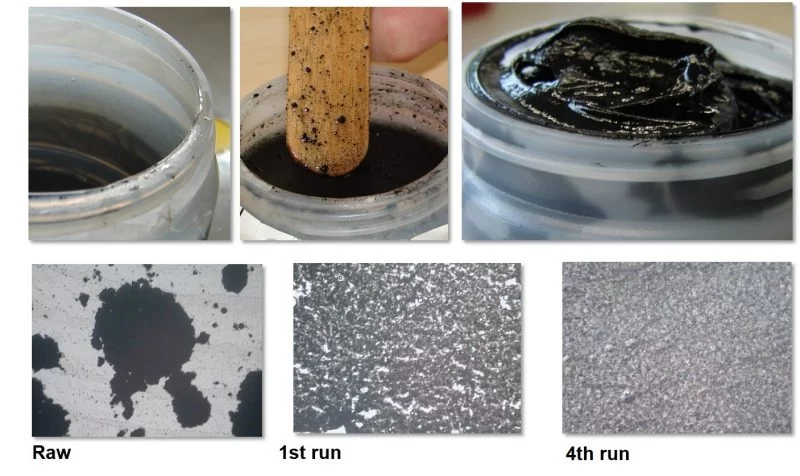

Instead of a chaotic impact, it applies precisely controlled, progressive shear between three horizontally aligned rolls.

How the Shear Mechanism Works

Material passes sequentially through:

Feed roll

Center roll

Apron roll

Each roll rotates at increasing speed, creating a defined shear gradient. Adjustable roll gaps — often in the micron range — allow operators to dial in shear intensity with precision.

This enables:

Deagglomeration of CNT bundles

Uniform distribution throughout the matrix

Preservation of nanotube aspect ratio

Stable rheological behavior

Repeatable batch-to-batch performance

Rather than brute force energy, the process relies on gap-controlled shear refinement.

Where Three Roll Mills Create Competitive Advantage

CNT dispersion is not a laboratory curiosity. It is a scale-up challenge with direct commercial impact.

1. Energy Storage (Battery Electrode Slurries)

Uniform CNT distribution creates more effective conductive pathways in cathode and anode formulations. The result:

Lower internal resistance

Improved rate capability

Reduced inactive material loading

Better cycle performance

Even slight improvements in conductive network formation can yield measurable gains in battery efficiency.

2. Conductive Inks & Printed Electronics

In screen printing, gravure, or inkjet applications, dispersion quality determines:

Line consistency

Predictable sheet resistance

Print resolution

Rheological stability

Agglomerates lead to clogging, inconsistent conductivity, and rejected batches. Controlled shear enables the uniformity required for high-precision printed electronics.

3. EMI Shielding & Advanced Coatings

EMI shielding systems depend on network continuity. A Three Roll Mill helps achieve:

Lower CNT loading to reach the percolation threshold

Cost savings from reduced filler use

Improved film uniformity

Lower filler loadings also maintain mechanical properties and reduce weight.

4. Advanced Structural Composites

In structural conductive composites, proper CNT dispersion:

Enhances mechanical reinforcement

Improves fracture resistance

Reduces defect concentration

Poor dispersion creates stress concentrators. Controlled shear mitigates that risk.

5. R&D to Production Scale-Up

One of the strongest advantages of the Three Roll Mill platform is scalability.

Formulation scientists can:

Precisely adjust roll gaps

Document shear conditions

Reproduce dispersion parameters

Transition from lab to pilot to production

This controlled, measurable process environment supports predictable scale-up — critical in high-value advanced material development.

Why the EXAKT Three Roll Mill Platform Is Engineered for CNT Processing

EXAKT systems are designed for precision dispersion applications, not general-purpose mixing.

Key technical advantages include:

Micron-level roll gap adjustment

Progressive shear refinement

Repeatable operating parameters

Minimal contamination risk

Controlled thermal impact

When processing CNTs, the objective is not maximum energy input. It is an optimized shear application.

For formulators working in conductive systems, that distinction directly impacts performance, yield, and cost efficiency.

Explore the EXAKT Three Roll Mill product line here:

https://exaktusa.com/three-roll-mill-products/

Final Perspective: Dispersion as a Strategic Differentiator

In advanced materials markets, dispersion quality separates commodity processing from engineered performance.

With CNT systems:

Shear control matters more than brute force

Microstructure determines conductivity

Repeatability drives commercial success

A Three Roll Mill does not simply blend materials.

It allows you to engineer dispersion with intent.

If you are developing CNT-based formulations and want to optimize conductivity, rheology, and material efficiency, a controlled shear platform should be part of your evaluation process.