Choosing the Right EXAKT Ointment Mill for Your Pharmacy

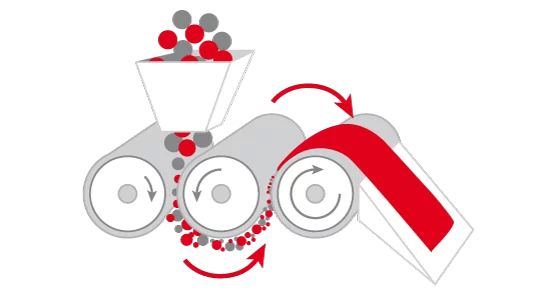

Matching the Right Ointment Mill to Your Compounding Needs Not all pharmacies compound at the same volume or complexity level. That’s why EXAKT offers multiple ointment mill models—each designed to meet specific workflow demands while maintaining the same core milling performance. Two of the most popular models in pharmacy environments are the EXAKT 80S Plus and the EXAKT 50+ Rx 200. EXAKT 80S Plus: The Industry Standard for Compounding Pharmacies The EXAKT 80S Plus is widely regarded as the benchmark