5 Reasons EXAKT Ointment Mills Are Better Than Mixers

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg Germany concluded that the quality of compounds processed with EXAKT ointment mills is better than those processed with electric mixing systems. The particle size is smaller and the particle size distribution is more narrow. Ointment stability is better. Temperatures do not […]

EXAKT Ointment Mills Get Results

EXAKT three ointment mills deliver results that are consistent and reproducible. A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with EXAKT ointment mills is better than those processed with electric mixing systems. The study highlighted the following conclusions: The particle size […]

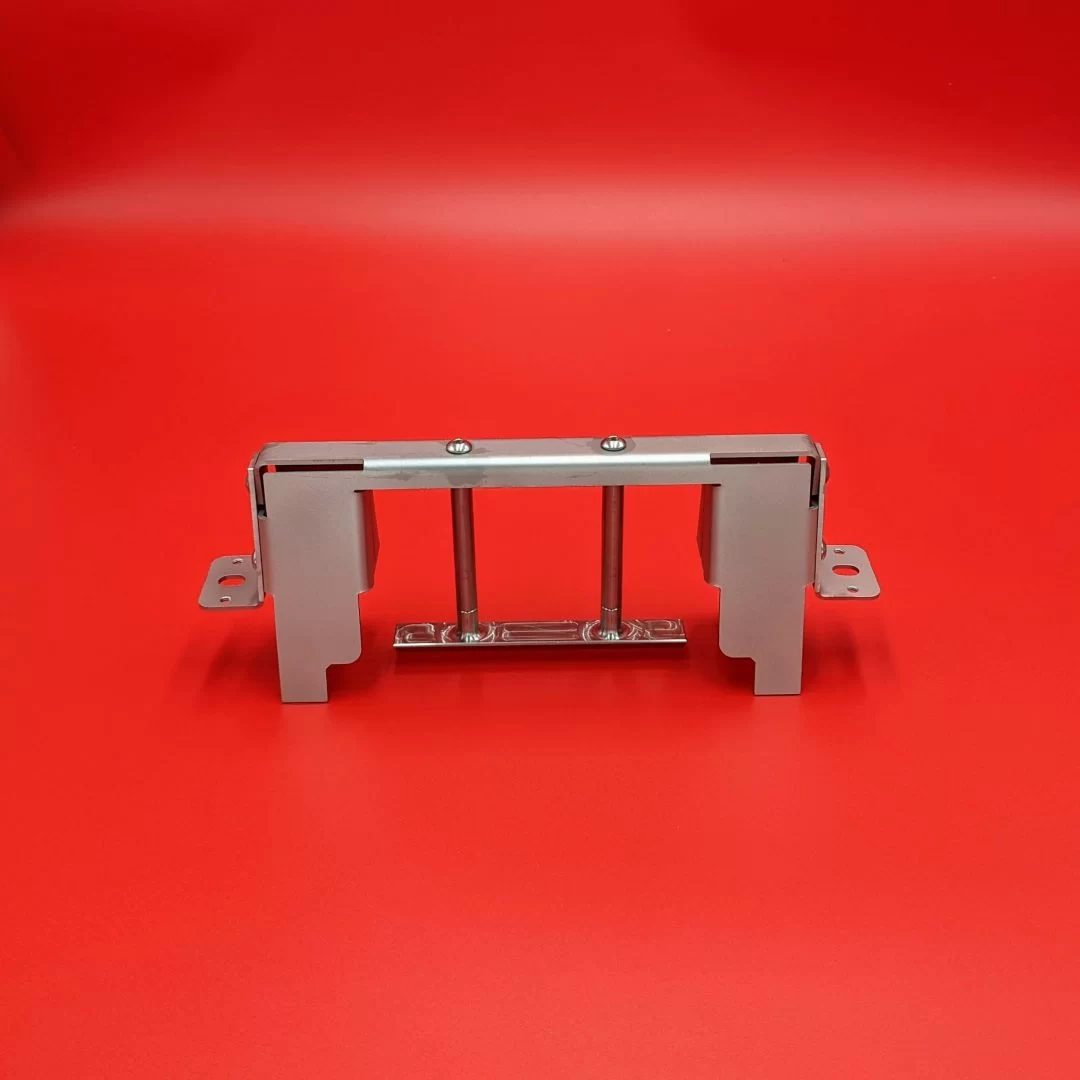

Make Your Mill Safer With the Nip Guard

Add an extra layer of safety to your EXAKT 50 I three roll mill. Order here. Make a great mill even better Add another layer of safety Attaches fast – no tools needed Save $$ on costly repairs Keep more of your spatulas Designed for EXAKT 50I use only.

6 Great Features of the 80S Plus

The new EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control, and the choice of ceramic and metallic rollers, the new 80S Plus was designed for processing a wide range of different materials. This three roll mill works well […]

5 Reasons to Choose EXAKT Ointment Mills

Because precision matters. EXAKT produces the most precise, safe, and user-friendly machines in their respective industries. These products are an investment meant to last. The “Made in Germany” stamp you see on each of our machines embodies the meticulous attention to detail and pride in workmanship. Our equipment is something special, and we want you […]

It Makes Cleaning Three Roll Mills Safe and Easy

Add another layer of safety to your mill with this cleaning guard. The cleaning bar keeps paper towels from getting stuck in the nip. For use with the EC Plus and 50I. Order online here. Or you can email exaktorders@exaktusa.com. To see more EXAKT three roll mill videos, click here.

Why Choose EXAKT Ointment Mills

Because precision matters. Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide. Expertise – Extensive knowledge of applications with a wide variety of materials. Service – Factory-trained technicians are available to help repair and extend the life of your equipment. Products – Machines are made for the customer with […]

The EXAKT 80S Plus

The new EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control and the choice of ceramic and metallic rollers, the new 80S Plus was designed for processing a wide range of different materials. This three roll mill works well […]

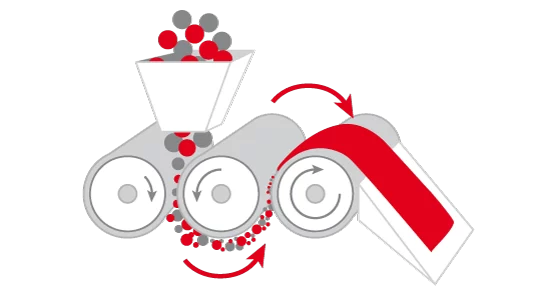

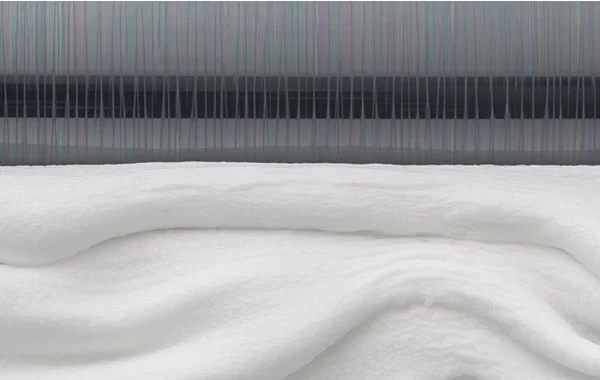

EXAKT Three Roll Mills for Cosmetics

Cosmetic chemists use EXAKT three roll mills to achieve greater color brilliance and fineness in medium to high viscosity substances. EXAKT mills are excellent for breaking open agglomerates and reducing particle sizes to the micron level. Precise, compact, and efficient, EXAKT three roll mills are among the most user-friendly devices in the cosmetic industry. Learn […]

Conventional Mixing vs. EXAKT Milling

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems. Particle size is smaller. Particle size distribution is narrow. Ointment stability is better. Temperatures do not increase significantly during processing. […]