EXAKT 50I Three Roll Mill

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective

From the food industry to nanotechnology, EXAKT three roll mills are used in a wide variety of industrial and research applications. No matter which paste must be processed, the EXAKT three roll

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include: Disperse the difficult – tangled CNT, especially in viscous pastes

Keep your mill performing as it should. Often times what you think is a problem with the mill is really just a worn out scraper and/or guides. If used on

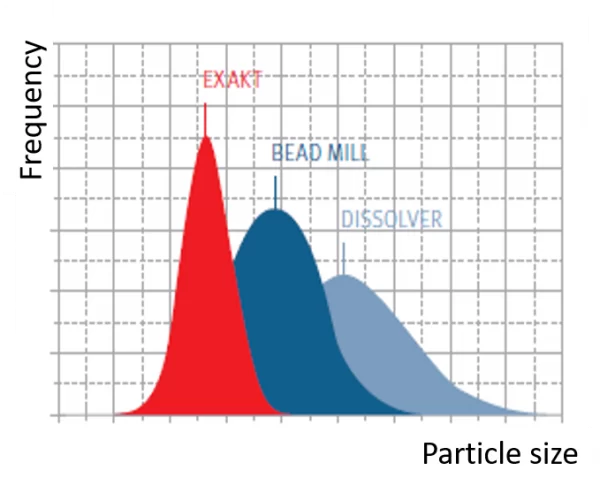

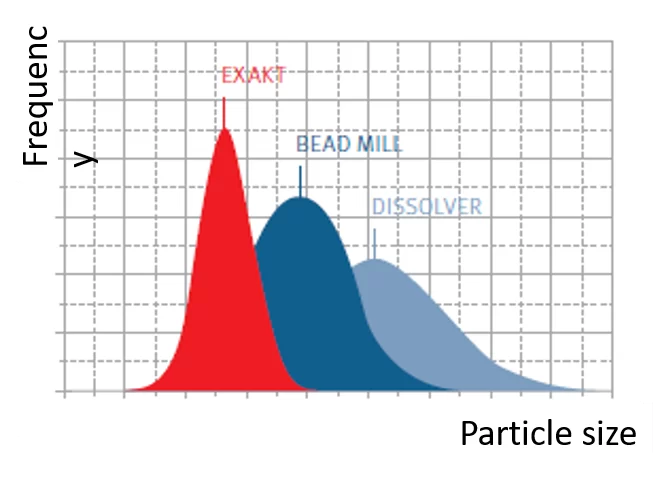

Only the ointment mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones. The shear rate between the rollers is the

Problem: Labs are using equipment originally designed to cut wood, stained glass, and even butchered meat. This has led to poor quality samples and extremely dangerous working conditions. Solution: EXAKT’s

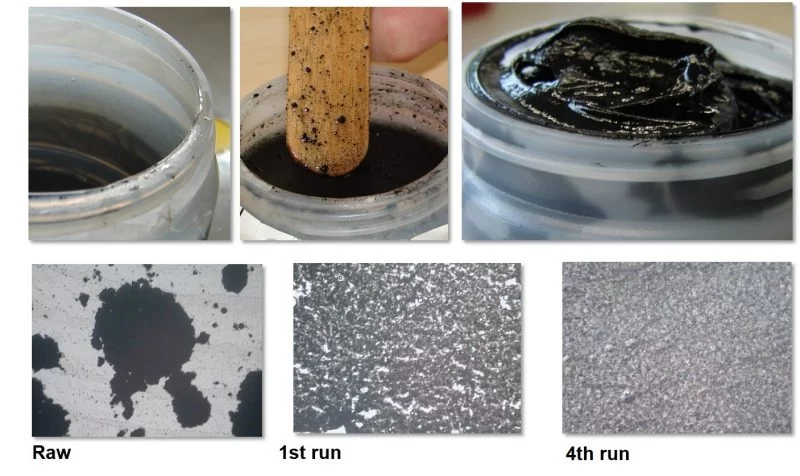

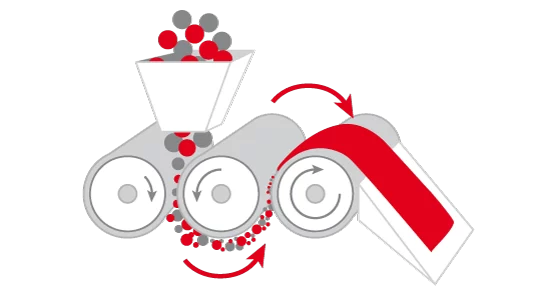

A three roll mill utilizes high shear force to disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at

Because precision matters. Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide. Expertise – Extensive knowledge of applications with a wide variety of materials.

Prevent Downtime, Improve Performance EXAKT’s preventative maintenance program extends the life of your mill and reduces downtime. EXAKT ointment mills last a long time, and a little preventative maintenance will add