When should you consider an additional mill?

Whether you already own an EXAKT ointment mill or a mill from another manufacturer, the EXAKT 50EC+ is the best choice when considering additional mills. The EXAKT 50EC+ is a modular ointment mill, designed with removable rollers for easy, efficient cleaning. With the purchase of an extra set of rollers, you can increase efficiency in your pharmacy by having […]

The Ointment Mill Process

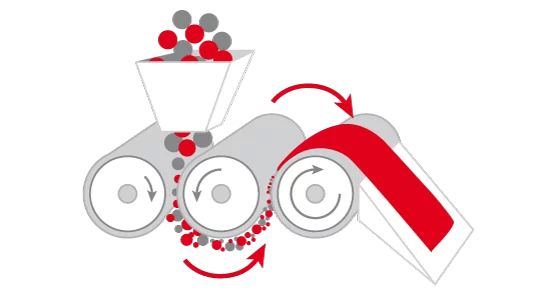

An ointment mill utilizes high shear force to reduce particle sizes, disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The whole product is pulled through the gap between the rollers, resulting in a precise, controllable, and […]

How to Clean Your Ointment Mill

CLEANING YOUR EXAKT OINTMENT MILL For everyday cleaning between formulations, alcohol and a soft cloth or paper towel are the best things to use. Do NOT spray the alcohol on the rollers or pour the alcohol into the gap when the machine is running. Put the alcohol on a paper towel or cloth and hold […]