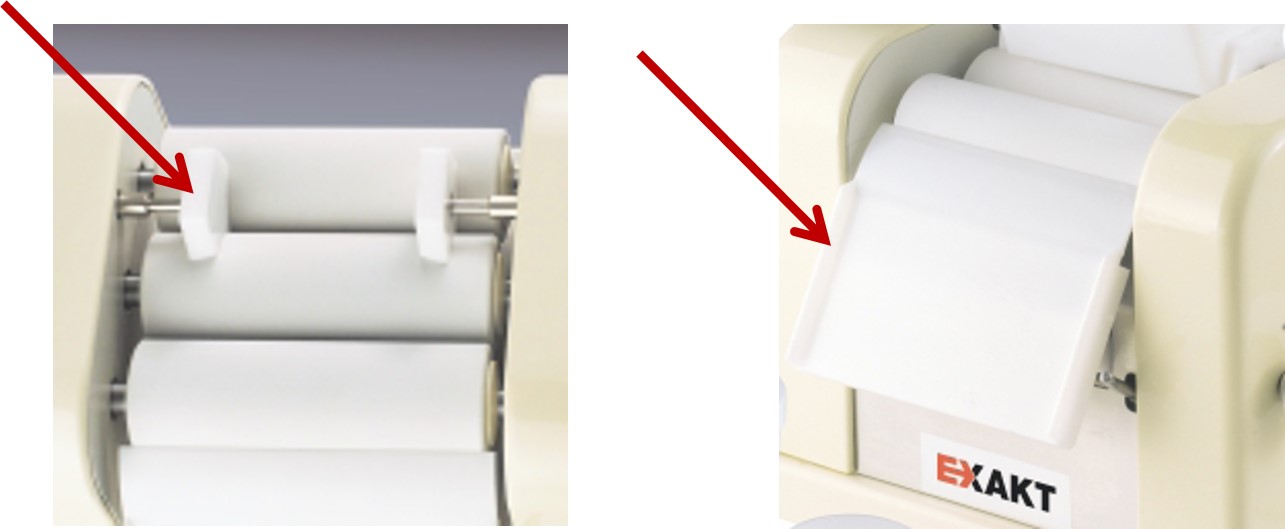

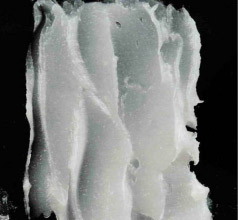

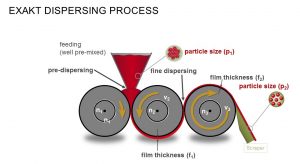

For producing truly elegant preparations of creams, ointments or gels there is no tool more effective or more complete than an ointment mill. And the EXAKT 50 EC+ delivers more control in making that elegant preparation.

HIGHLIGHTS

› Roller gap to 10 μm

› Precise setting of the roller gap, no dry running possible

› Up to 5 l/h throughput with a gap width of 10 μm

› Continuously adjustable circumferential speed of the rollers

› Interchangeable roller set

› Ceramic or hardened chrome rollers

› Precise one-hand adjustment, continuous and with scale

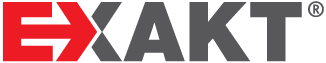

› Self-adjusting scraper knife

› Overload protection

.

Recent Comments