LED Lighting

For optimal illumination of the workspace

Mobility Set

Removable castors to move device easily

Water Pistol

For fast cleaning of the entire system.

For optimal illumination of the workspace

Removable castors to move device easily

For fast cleaning of the entire system.

Key elements of the saw such as doors, the top of the work table or the upper pulley of the saw blade are easy to remove without tools and can be cleaned under running water. Rinsing immediately after use removes any tissue residues from the band, subsequent samples are not affected and the overall system is far easier to clean.

Replacing key parts will extend the life of your saw and improve its performance. The single best way to improve performance is to make your cutting band is replaced annually.

Whether you need replacement parts, repairs, or advice, EXAKT has factory-trained technicians and expert technical support to help you. We’ll make sure your equipment works the way it should.

Watch and learn from videos designed to improve your experience:

EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

Diamond Band – Special characteristics:

Diamond Band – Special characteristics:

Distortion-free / corrosion-free stainless steel

Single diamond layer, nickel embedded

Different band thicknesses and grain sizes

Minimized kerf-loss

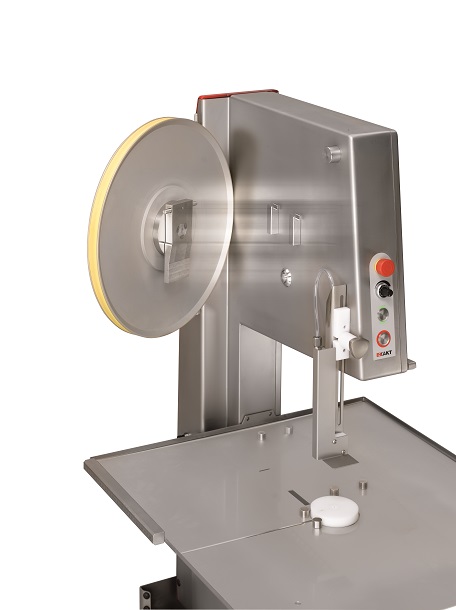

EXAKT’s 312 Pathology Saw has been designed to safely gross bone, tissue, and metal implants without the worry of injuring yourself.

Developed for the requirements of pathology

Freehand cuts down to 1 mm possible

Minimal risk of injury to the operator

Mobile and universal use

Very easy to operate

For fresh tissue, and bone with implants or screws

Experience – More than 30 years of thin sectioning experience and over 2,800 units in use around the world.

Expertise – Leverage our 30 years of experience for your specific application.

Service – our factory-trained technicians are available to help repair and extend the life of your equipment.

Products – Our products offer the largest variety and flexibility for sample preparation applications.

Precision – nothing says precision and quality like German engineering.

EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

Supports precise positioning of the sample to the cutting band

Reduces aerosolized bone and tissue matter

Controls water from splashing outside the saw

Manual adjustment for parallel cuts, including scale

Available in three sizes ( 30, 100, and 200 mm)

The EXAKT 312 Diamond Band Saw was developed to meet the special requirements of pathology and anatomy (human and

veterinary) medicine. With the EXAKT 312, even the smallest cuts down to about 1 mm can be made freehand with almost no risk of cuts to the operator. Whether it’s soft tissue, bones or implants in the bone-tissue composite, it can all be cut effortlessly and quickly. Not

only this, but it does it with a cut surface quality surpassing every other process available. An initial assessment of the cut can generally be made right away. Outfitted with a variety of different options, the EXAKT 312 can be adapted to individual handling and operating comfort needs.

The EXAKT 312 is very easy to operate and clean. Band changes can be made without tools or adjustment. The stainless-steel housing is consistently designed for good water and tissue drainage. For thorough cleaning and disinfection, modules can be quickly removed without the use of tools.

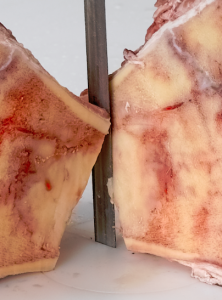

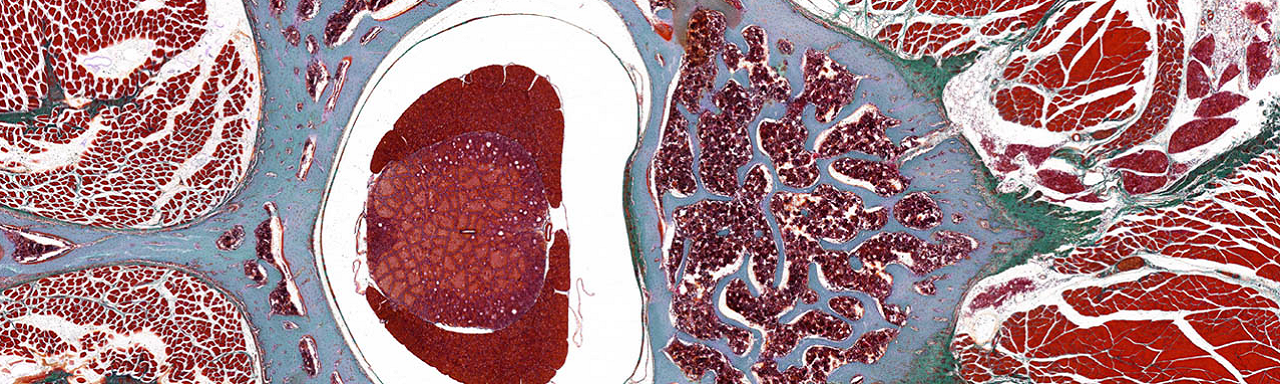

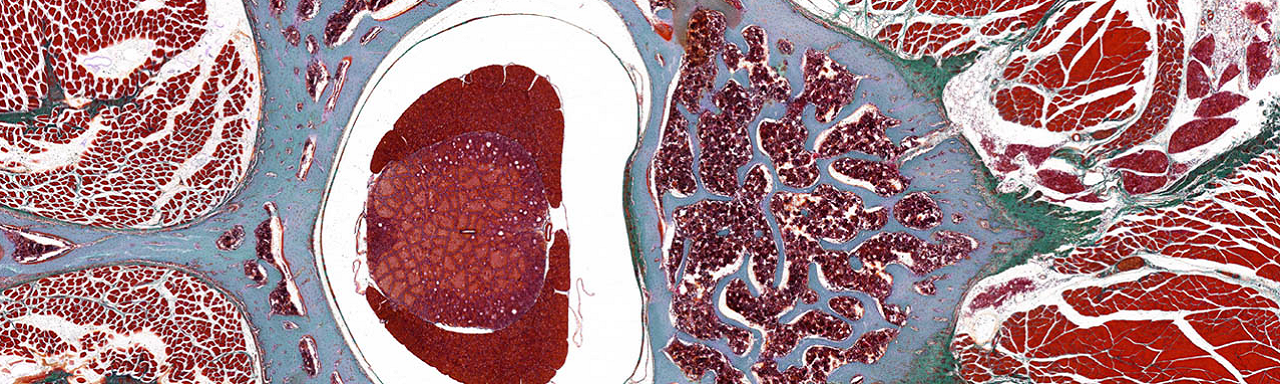

The EXAKT 312 Diamond Band Saw doesn’t cut, it grinds very precisely. This is the reason for the outstanding surface quality

of the cut surface. Complete preservation of the sample with a surface free of artifacts, micro-fractures and breakouts enables

immediate inspection and assessment of the sample. Even the cell information of very different tissue densities remains

intact. Since the cutting band grinds rather than cuts, there is no immediate risk of injury to the operator in case of inadvertent

contact, which is a first in work safety! Tricky samples with implants, in particular, can be precisely

and safely processed. Guiding the cut is easy and precise, and the process is clean and quiet. Water cooling also reduces dust

development and ensures that the sample doesn’t overheat.

› Superior cut surface quality

› Maximum working safety enables cuts down to 1 mm

› Integrated water cooling prevents overheating of the sample, reduces dust development and keeps the cutting band cleaner

› Cutting band changed without tools or readjustment

› Fast and easy cleaning through the tool-less removal of contaminated modules

› Reliable and time-tested – Hundreds of systems are already in use around the world

Recent Comments