For everyday cleaning between formulations, alcohol and a soft cloth or paper towel are the best

things to use. Do NOT spray the alcohol on the rollers or pour the alcohol into the gap when the

machine is running. Put the alcohol on a paper towel or cloth and hold it against the roller tightly

while you turn the roller with the hand wheel.

When you start to get a buildup you can use an abrasive to clean the rollers. You don’t want to do

it too often because it will remove some of the porcelain over time.

1. Do not use Ajax or Comet cleansers (even SoftScrub). They have bluing crystals that can

leave the blue dye on the roller. Find a form of SoftScrub that is made of

completely white powder. Bon Ami is another acceptable cleanser. You can find this in

big box stores with the other cleansers. Make a slurry of it with either water or Goo-Gone

(a citrus based liquid that cuts oils) and put it on the tip of a sponge and gently scour the

rollers. Other people use baking soda in light oil to do the same thing. It is possible to

put some of these slurries or Soft Scrub in the back gap and run the mill. One or two

passes will suffice. Running additional passes has the potential to create larger pores in

the porcelain.

2. Fast Orange Hand Cleaner can also be used. It can be found at retailers like Wal-Mart,

Sam’s, Home Depot, and auto parts stores. It’s a pumice based hand cleaner with the

consistency of jelly. When there is a badly stained roller, run it through the mill with the

gaps slightly open. One pass usually takes off any stain or congealed product. Do NOT

use this for more than one pass. The pumice is much more abrasive than the cleanser or

baking soda. You can put a little on a damp sponge and spot clean with it gently.

Once you’ve completed any of these steps, thoroughly clean the rollers with soap and water.

Then remove that residue with alcohol before running a new product.

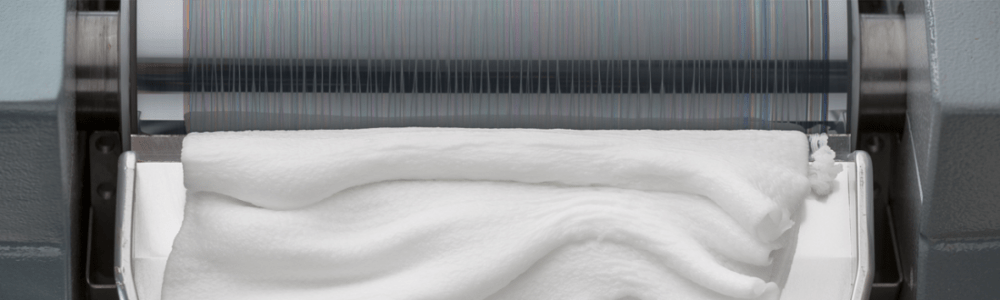

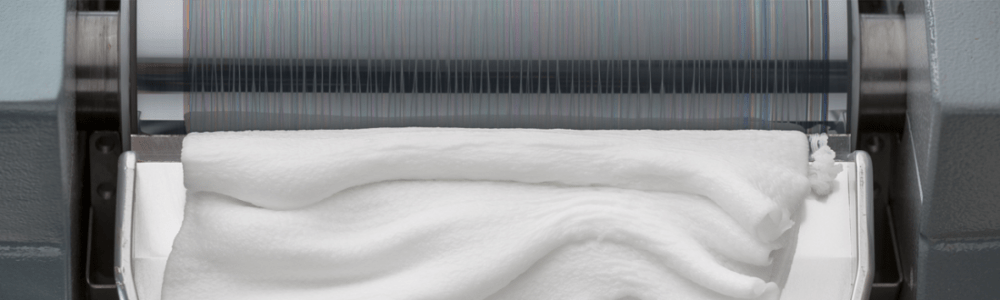

Safety Warning – Many pharmacies are running back-to-back ointments and need to clean their

mills quickly. So rather than turning the rollers with the hand wheel they leave the machine running

while they clean. Not only is this unsafe for the technician, but it makes it easy to get the

cleaning cloth caught in the gap. When this happens there is a risk not only to the technician but

to the machine and its precision. It is possible to bend the shafts of the rollers if something too big

is pulled in and the repair/replacement cost can be in the thousands of dollars.

Recent Comments