Improved safety standards, easy operation, and even more precise adjustment of the gap.

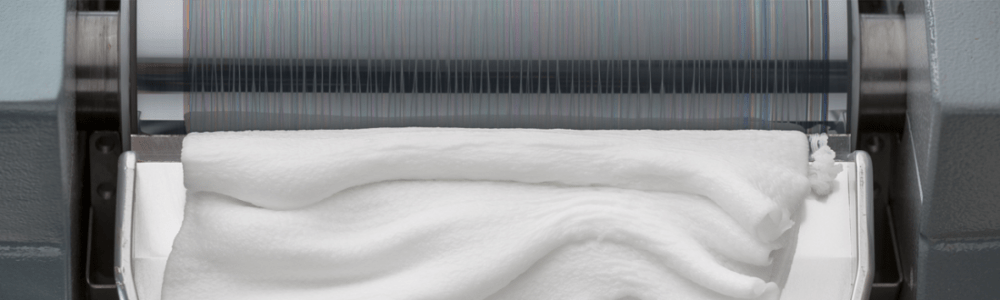

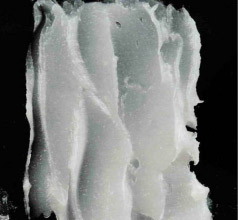

The EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control, and the choice of ceramic and metallic rollers, the 80S Plus was designed for processing a wide range of different materials.

This three roll mill works well with both small quantities in the laboratory and larger production quantities. Different working widths and exceptional safety devices ensure ideal working conditions for many products.

- Easily monitor speed, temperature, production timer, and power consumption on the color display

- Adjustable gap range: 5 to 230 μm

- Variable throughput from as little as 10 ml up to 18 l/h at a 10 μm gap

- Covers made of stainless steel blasted or optional electro-polished

- Roller materials: Chrome, tungsten carbide, aluminum oxide, or silicon carbide

- Meets or exceeds safety standards specified in ANSI

Learn more about the 80 S Plus

Recent Comments