A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg Germany concluded that the quality of compounds processed with EXAKT ointment mills is better than those processed with electric mixing systems.

- The particle size is smaller and the particle size distribution is more narrow.

- Ointment stability is better.

- Temperatures do not increase significantly during processing.

- Ointments are softer consistency with lower flow limits

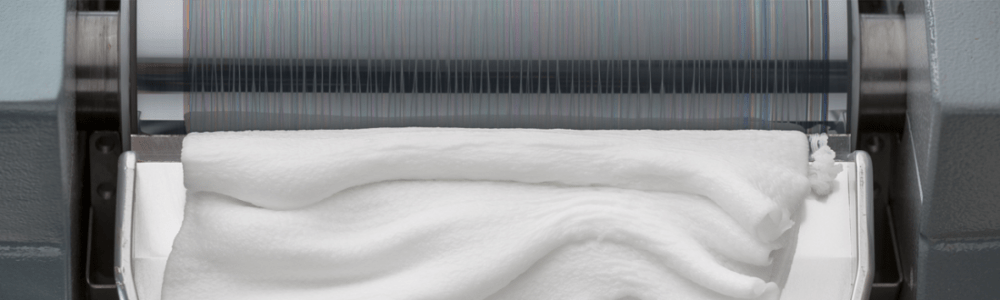

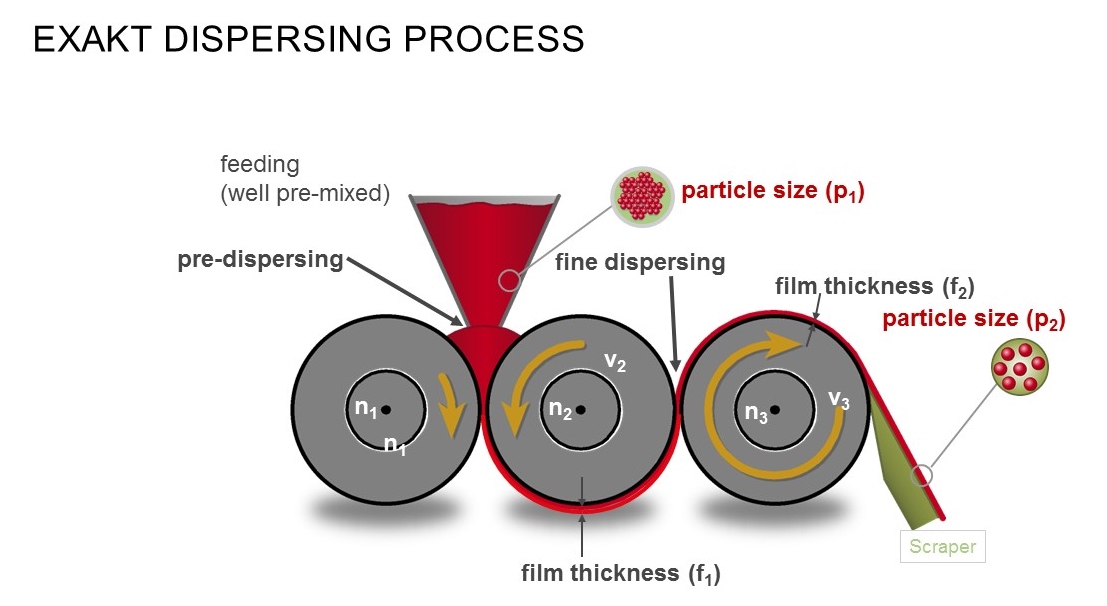

- Three roll mills allow for quality control during processing.

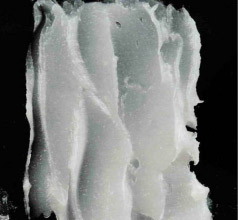

Substance processed with conventional mixing procedure: crystalline substances are still clearly visible.

Recent Comments