Make a great mill even better

- Add another layer of safety

- Attaches fast – no tools needed

- Save $$ on costly repairs

- Keep more of your spatulas

Designed for EXAKT 50 I use only.

Designed for EXAKT 50 I use only.

EXAKT three ointment mills deliver results that are consistent and reproducible.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with three roll mills is better than those processed with electric mixing systems. The study highlighted the following conclusions:

EXAKT three roll mills deliver results which are consistent and reproducible.

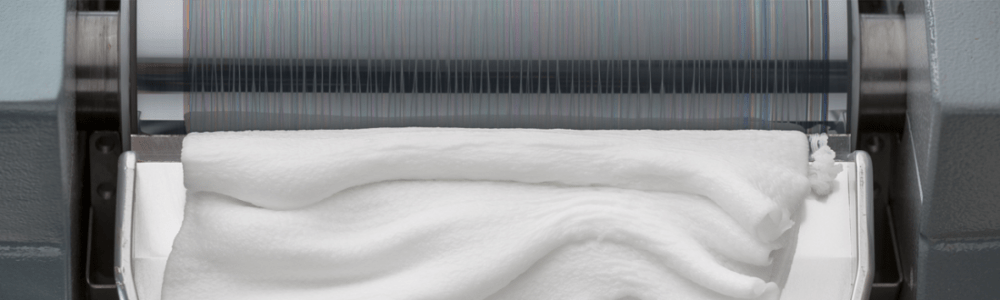

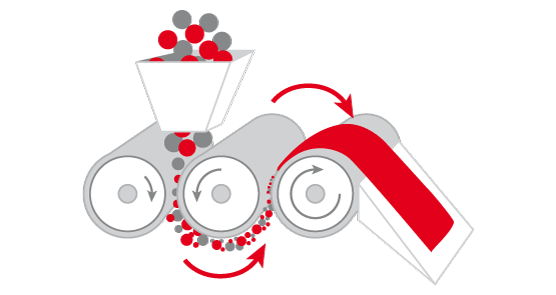

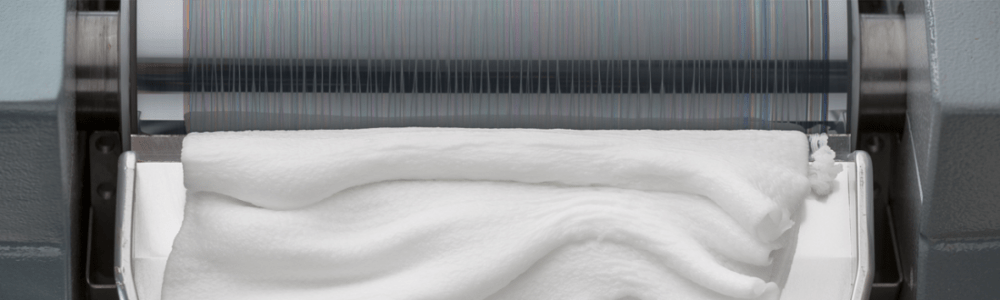

An ointment mill utilizes high shear force to disperse active ingredients, and homogenize viscous materials.

Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other.

The product is pulled through the gaps between the rollers. Active ingredients and powder clumps are broken up and homogenized, which removes grittiness and results in a high-quality topical. This gives your customers a pharmaceutically elegant and effective ointment.

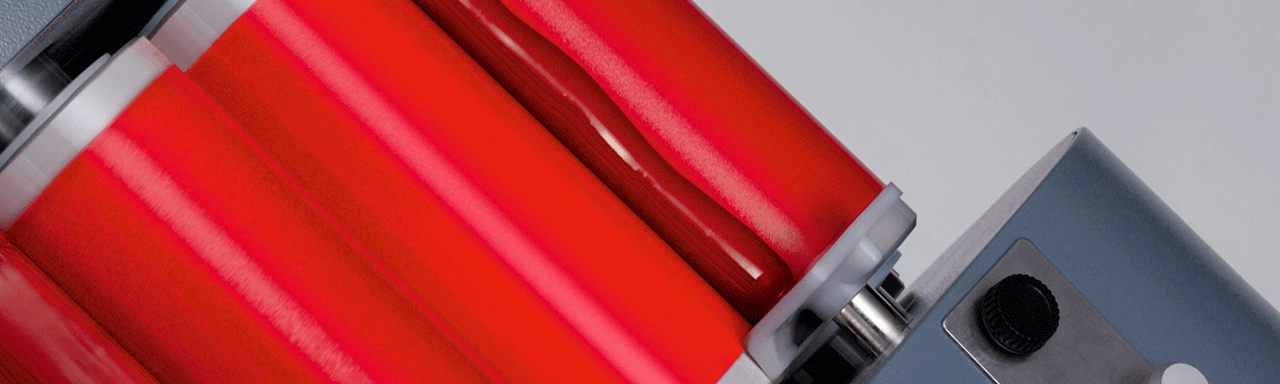

A three roll mill utilizes high shear force to disperse agglomerates, and homogenize viscous materials.

Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other.

The product is pulled through the gaps between the rollers. Agglomerates and powder clumps are broken up and homogenized.

Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

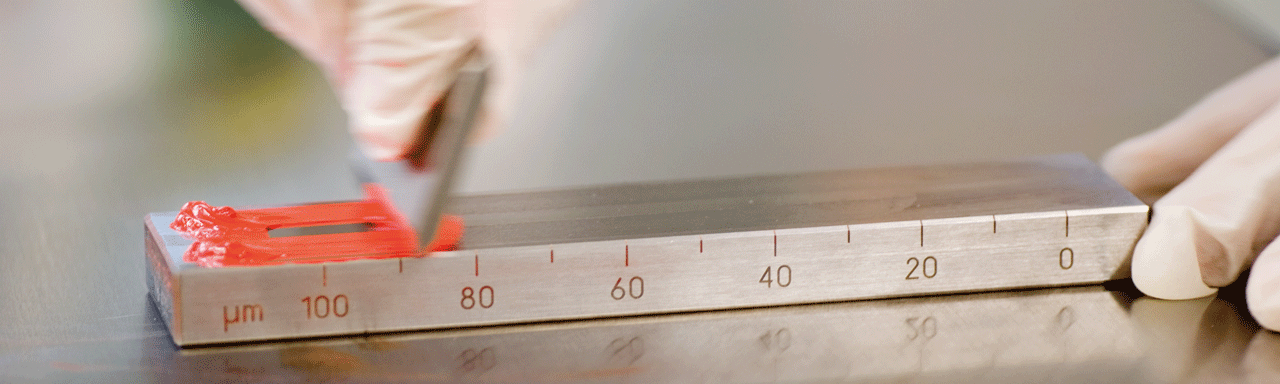

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

Experience – More than 60 years in dispersion, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

Chemical engineers use EXAKT three roll mills to improve penetration values and reduce noise in grease and lubrication formulations. Precise, compact, and efficient, these mills are among the most user-friendly devices in the industry. Learn more at EXAKTDispersion.com

For maximum fineness, higher throughput. The S-Line series is the entry point for achieving the finest dispersing results.

The S-Line series is the entry point for achieving the finest dispersing results.

Highlights:

Recent Comments