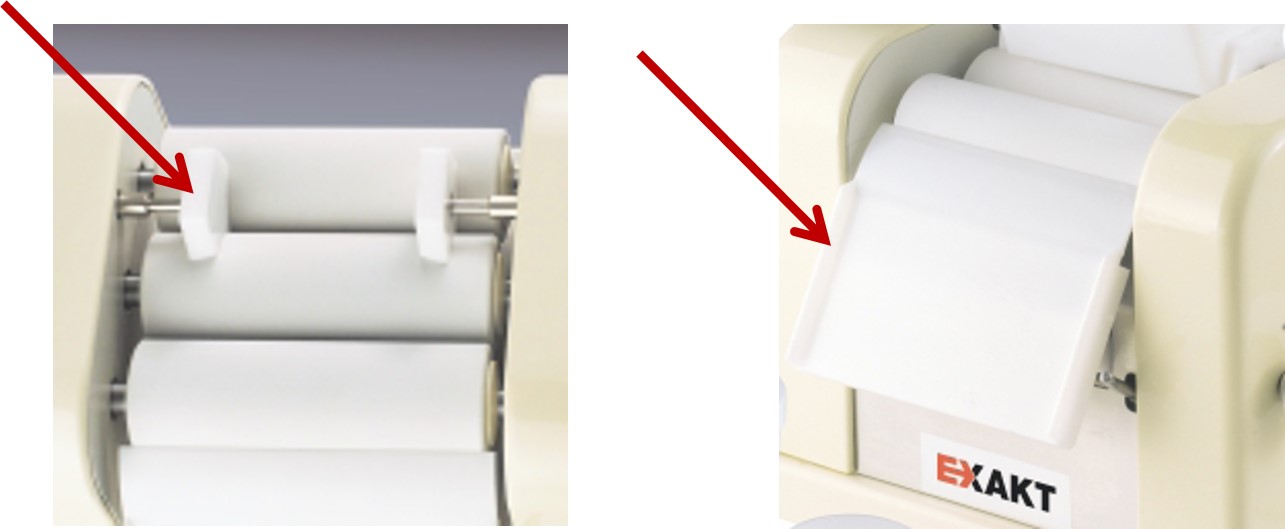

Whether you already own an EXAKT ointment mill or a mill from another manufacturer, the EXAKT 50EC+ is the best choice when considering additional mills. The EXAKT 50EC+ is a modular ointment mill, designed with removable rollers for easy, efficient cleaning. With the purchase of an extra set of rollers, you can increase efficiency in your pharmacy by having a clean set ready for your next preparation. Depending upon the product being milled, this machine produces output quantities from .02 to 7 liters per hour. Removable rollers cut down on cleaning time and cross-contamination between preparations! Remove and clean rollers with confidence! If you are processing 3-5kg at a time several times per week, or you anticipate continued growth of your topical business, you may need to consider the EXAKT 80 S Plus or EXAKT 80E Plus.

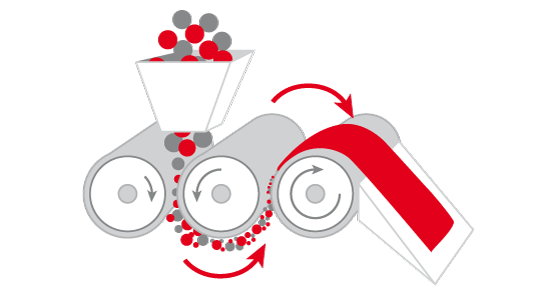

An ointment mill utilizes high shear force to reduce particle sizes, disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The whole product is pulled through the gap between the rollers, resulting in a precise, controllable, and narrow particle size distribution. The particle size can be easily and precisely controlled by adjusting the gap widths.

Step by Step Process:

- The premixed product is placed in the hopper.

- The product is drawn between the feeding and center rollers and finely ground.

- Adhering to the bottom of the center roller the product is transported to the gap between the middle and front roller.

- In this gap, the product is homogenized and ground for the second time.

- The finished product is removed from the front roller by the scraper system.

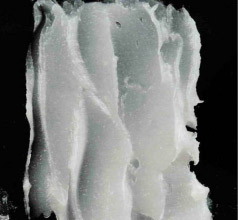

Substance processed with convention mixing procedure: crystalline substances are still clearly visible.

Substance processed with an EXAKT three roll mill: regular and fine consistency of the substance.

CLEANING YOUR EXAKT OINTMENT MILL

For everyday cleaning between formulations, alcohol and a soft cloth or paper towel are the best things to

use. Do NOT spray the alcohol on the rollers or pour the alcohol into the gap when the machine is

running. Put the alcohol on a paper towel or cloth and hold it against the roller tightly while you turn the

roller with the hand wheel.**

When you start to get a build up, you can use an abrasive to clean the rollers. You don’t want to do it too

often because it will remove some of the porcelain over time. Everyone has their favorite product so I’m

going to tell you about several of them.

1. Do not use Ajax or Comet cleansers (even SoftScrub). They have bluing crystals that can leave

blue dye on the roller. If you can find a form of SoftScrub that is made of completely white

powder this will be fine. I personally use Bon Ami cleanser. You can find this in the grocery store

with the other cleansers. I make a slurry of it with either water or Goo-Gone (a citrus based liquid

that cuts oils) and I put it on the tip of a sponge and gently scour the rollers. Other people use

baking soda in a light oil to do the same thing. It is possible to put some of these slurries or Soft

Scrubs in the back gap and run the mill. One or two passes are fine, but if you run it a lot you will

create larger pores in the porcelain.

2. There is a product called Fast Orange Hand Cleaner. You can find it at Wal-Mart, Sam’s,

Home Depot, auto parts stores etc. It’s a pumice based hand cleaner that is the consistency of

jelly. You can use this as well. When we have a particularly badly stained roller, we will run it

through the mill with the gaps slightly open. One pass usually takes off any stain or congealed

product. Do NOT use this for more than one pass. The pumice is much more abrasive than the

cleanser or baking soda. You can put a little on a damp sponge and spot clean with it gently.

Once you’ve done any of these, you should thoroughly clean the rollers with soap and water and then

remove that residue with alcohol before running a new product.

** Many pharmacies are running back-to-back ointments and need to clean their mills quickly.

So rather than turn the rollers with the hand wheel they leave the machine running while they

clean. Not only is this unsafe for the technician, but it makes it easy to get the cleaning cloth

caught in the gap. When this happens, there is a risk not only to the technician but to the

machine and its precision. It is possible to bend the shafts of the rollers if something too big

is pulled in and the repair/replacement can be costly.

Recent Comments