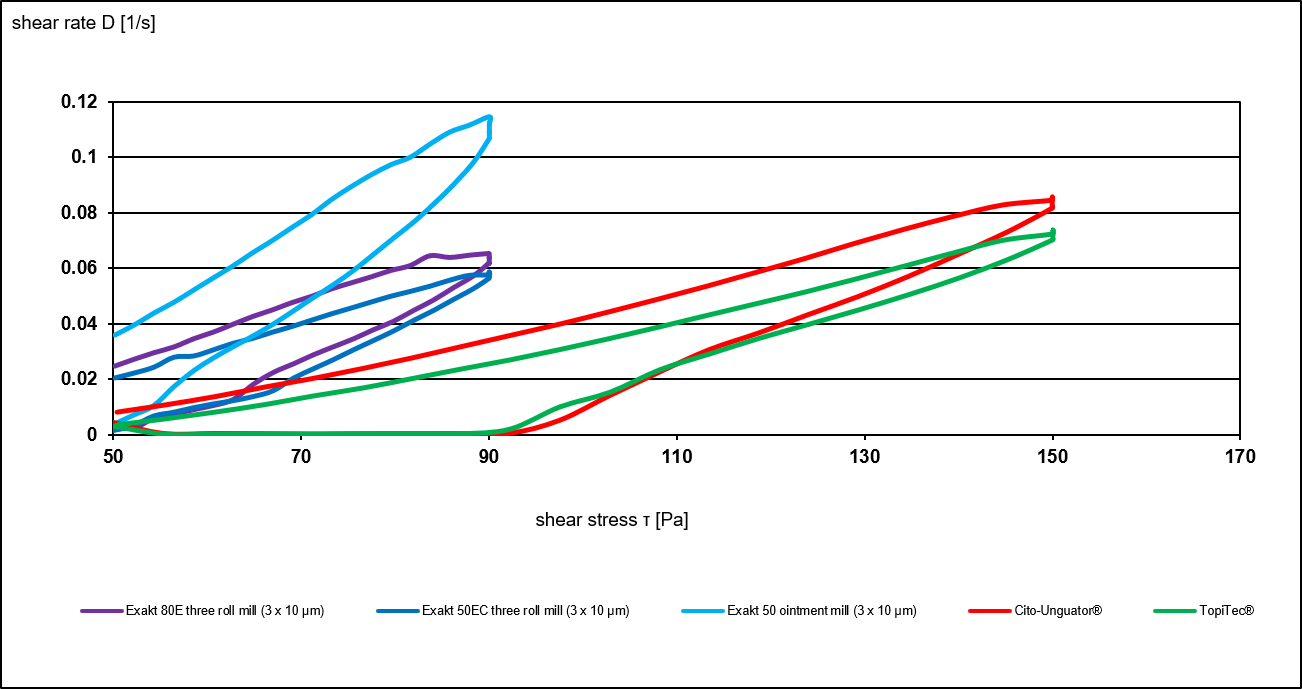

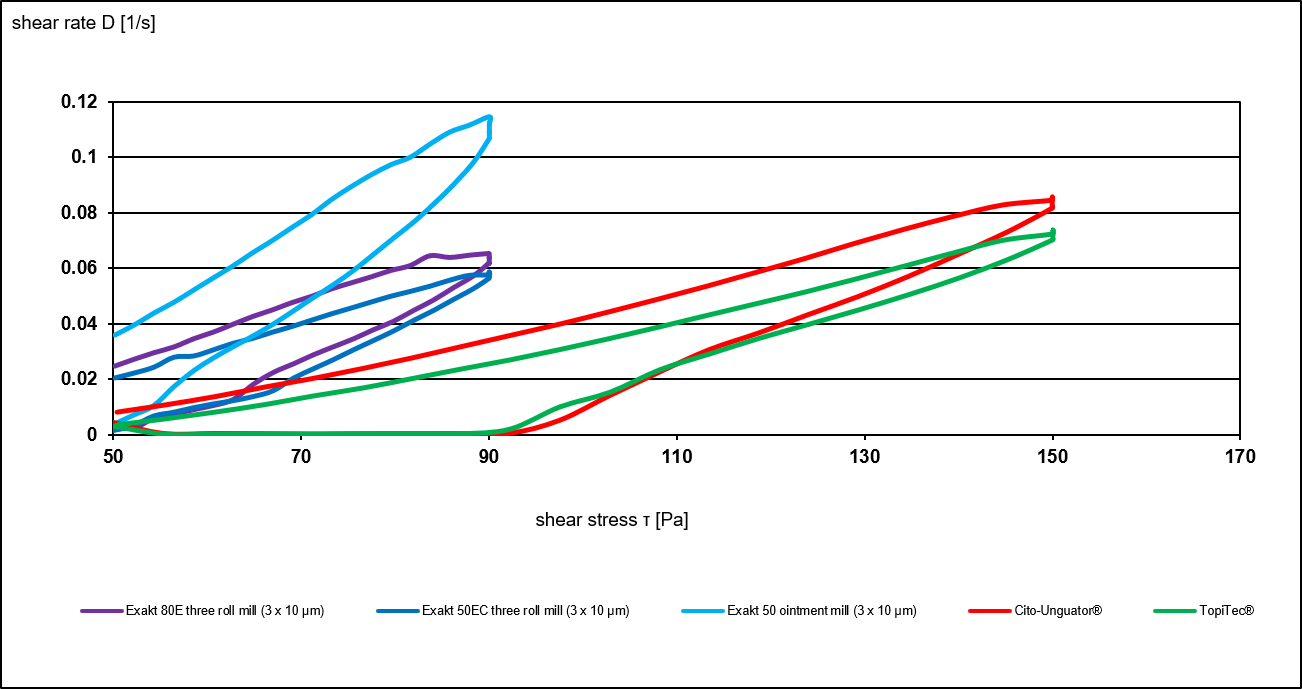

EXAKT ointment mills produced ointments with softer consistency and lower flow limits than those produced with EMPs, most likely due to the significant temperature increase of ointments processed with EMPs (electronic mortar & pestle).

EXAKT ointment mills produced ointments with softer consistency and lower flow limits than those produced with EMPs, most likely due to the significant temperature increase of ointments processed with EMPs (electronic mortar & pestle).

For producing truly elegant preparations of creams, ointments or gels there is no tool more effective or more complete than an ointment mill. And the EXAKT 50 EC+ delivers more control in making that elegant preparation.

HIGHLIGHTS

› Roller gap to 10 μm

› Precise setting of the roller gap, no dry running possible

› Up to 5 l/h throughput with a gap width of 10 μm

› Continuously adjustable circumferential speed of the rollers

› Interchangeable roller set

› Ceramic or hardened chrome rollers

› Precise one-hand adjustment, continuous and with scale

› Self-adjusting scraper knife

› Overload protection

.

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective in regard to fast cleaning, the avoidance of cross-contamination and downtimes due to changing the product. EXAKT 50 is indispensable for research, development, and training.

With more than 30,000 units installed around the world, the EXAKT Classic 50 is the best known and most accepted pharmaceutical ointment mill. The

Classic 50 ensures excellent results for topical, oral and suppository applications among others. When preparing ointments and creams containing crystallized ingredients, the EXAKT 50 is superior to even highly advanced mixing technologies.

Applications: suspension ointments, emulsions ointments or cream

Highlights:

Learn more about the Classic 50.

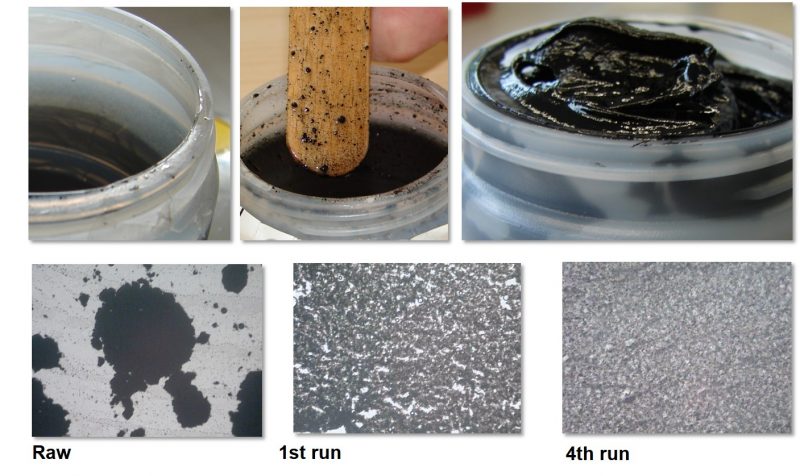

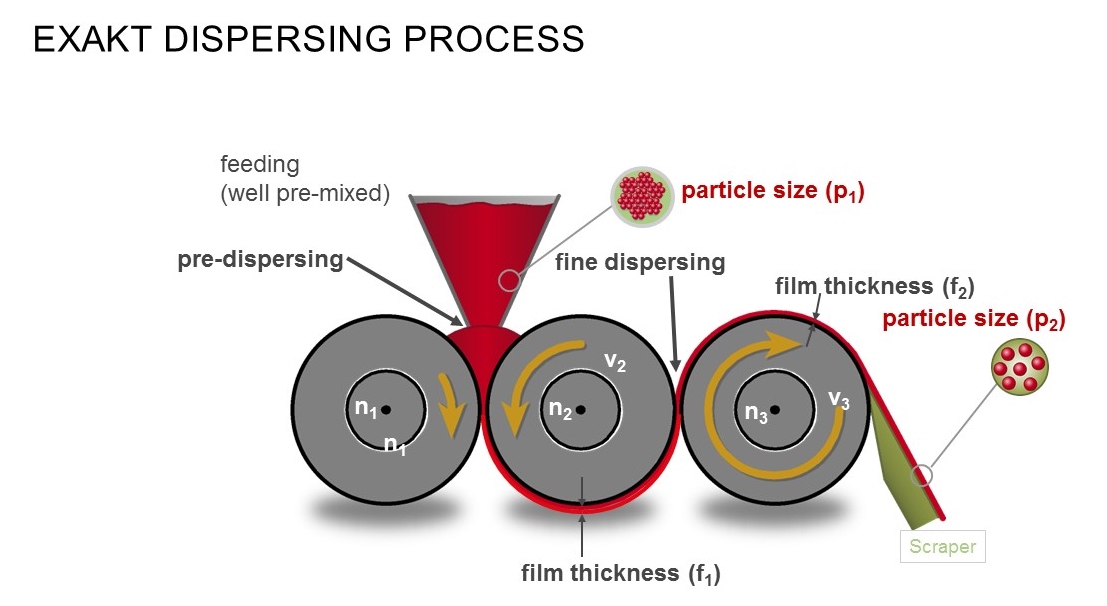

From the food industry to nanotechnology, EXAKT three roll mills are used in a wide variety of industrial and research applications. No matter which paste must be processed, the EXAKT three roll mills can break open all kinds of agglomerates. This creates substances of the greatest fineness and quality.

EXAKT’s preventative maintenance program extends the life of your mill and reduces downtime. EXAKT ointment mills last a long time, and a little preventative maintenance will add even more years of reliable performance.

New – FREE shipping!

We take the hassle out of shipping your mill. Schedule your tune-up, and we’ll send you a secure box with protective foam inserts, labels, and instructions.

For mills 2-5 years

Ensure performance

$350, free shipping

For mills 5 -10 years

Extend the life of your mill

$550, free shipping

For mills 10+ years

New mill performance without the new mill cost.

$1,200, free shipping

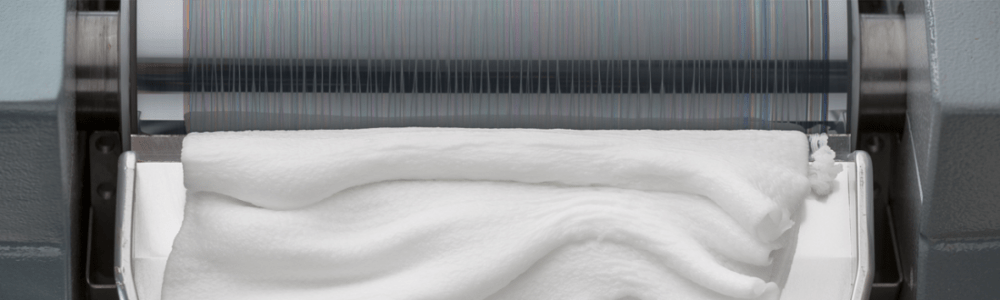

Check out the video below to learn more about cleaning your pathology saw. Cleaning your saw after each use will help improve the safety and performance of your machine.

Warning: Do not use disinfectants containing chlorine or aggressive disinfectants such as acetone or nitro thinner. Simply use alcohol-based disinfectant normally found in laboratories. Make sure they are alcohol based.

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include:

EXAKT’s electronic models (80E Plus, and 120E) give the most precise control and repeatability.

Whether it’s for research or production, learn more by calling or emailing our three roll mill experts.

800-866-7172 | info@exaktusa.com

The EXAKT 312 Pathology Saw can easily cut metal implants or screws that may be encountered during the grossing process, without destroying the sample. Even very small specimens can be cut safely and precisely!

Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

Recent Comments