Because precision matters.

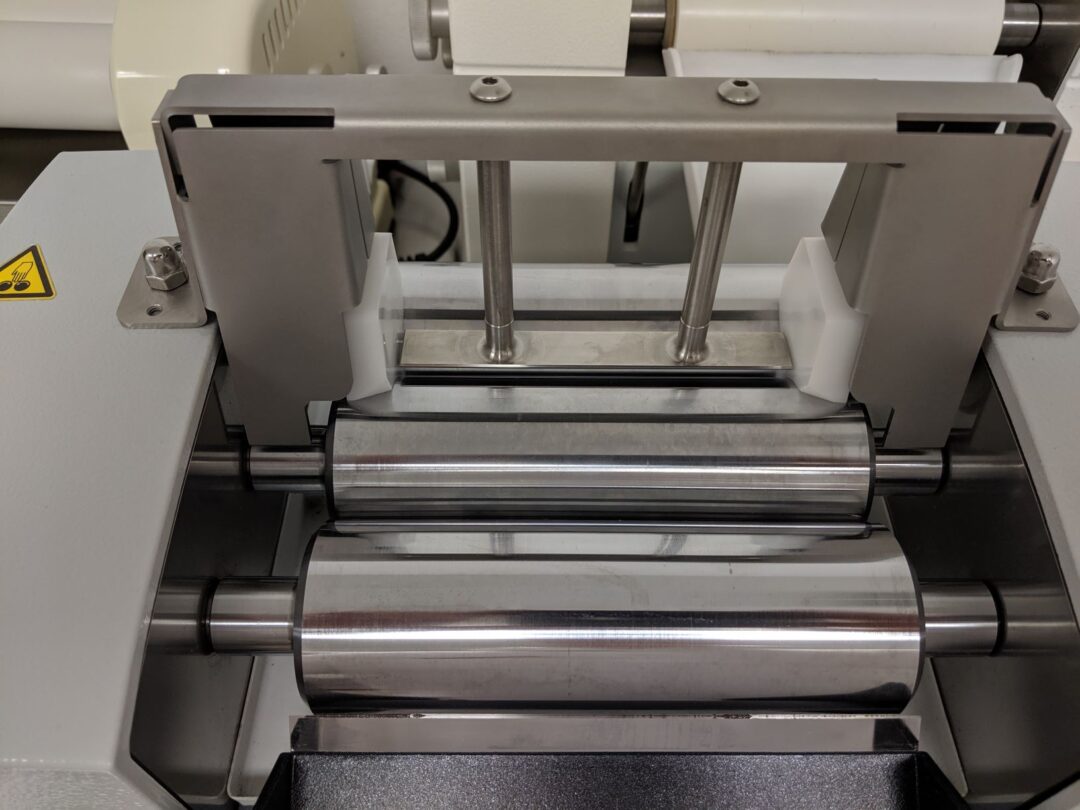

Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

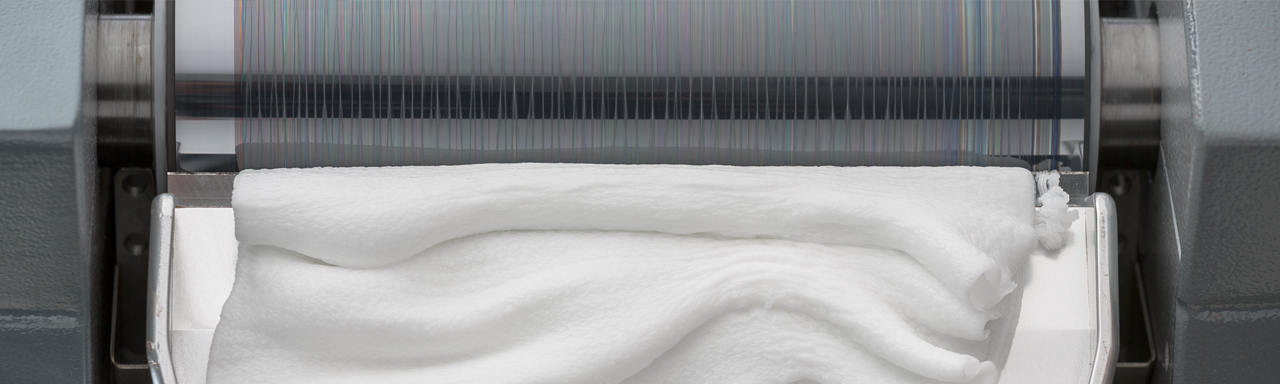

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

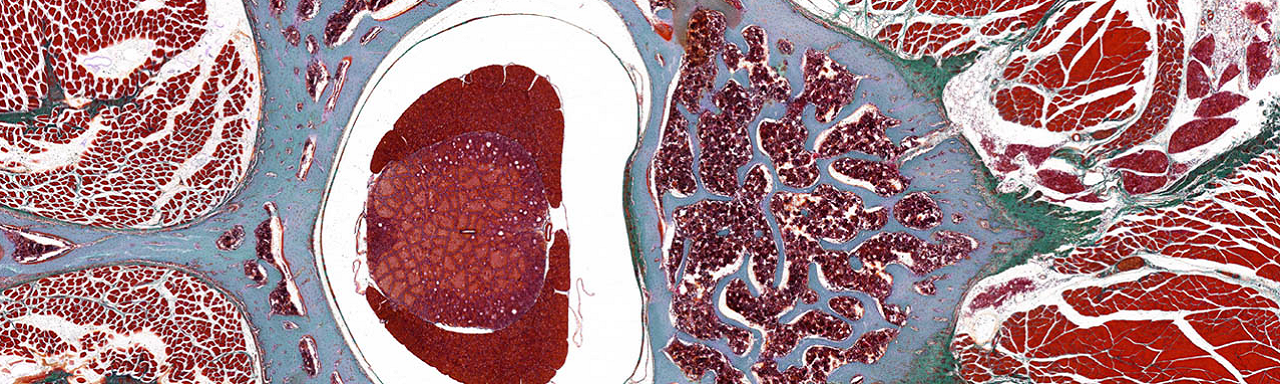

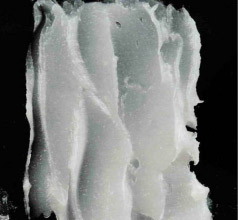

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

Recent Comments