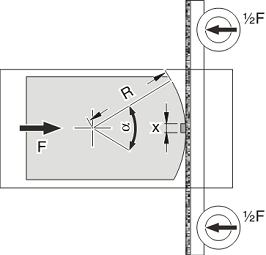

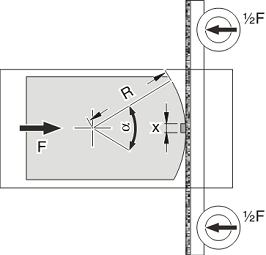

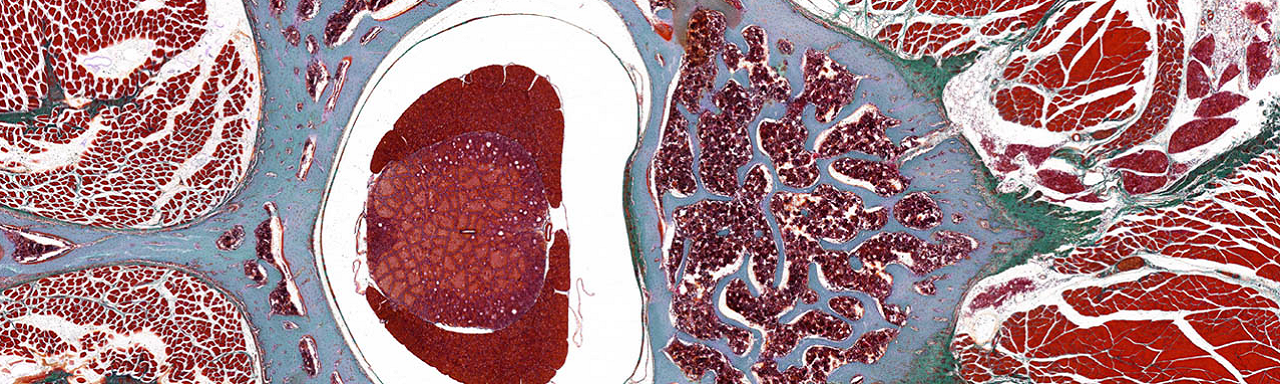

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

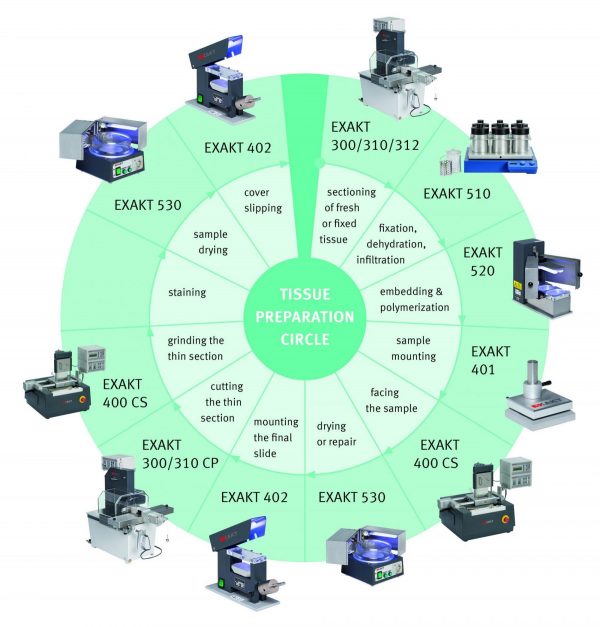

EXAKT Cutting and Grinding Technology enables you to approach sample examination in ways which simply weren’t possible for your application until now. Long service life, reliability, and minimal service expenditure also contribute considerably to the economical use of our systems.

Highlights:

› Almost no burring, fraying or tearing out on the cut surface

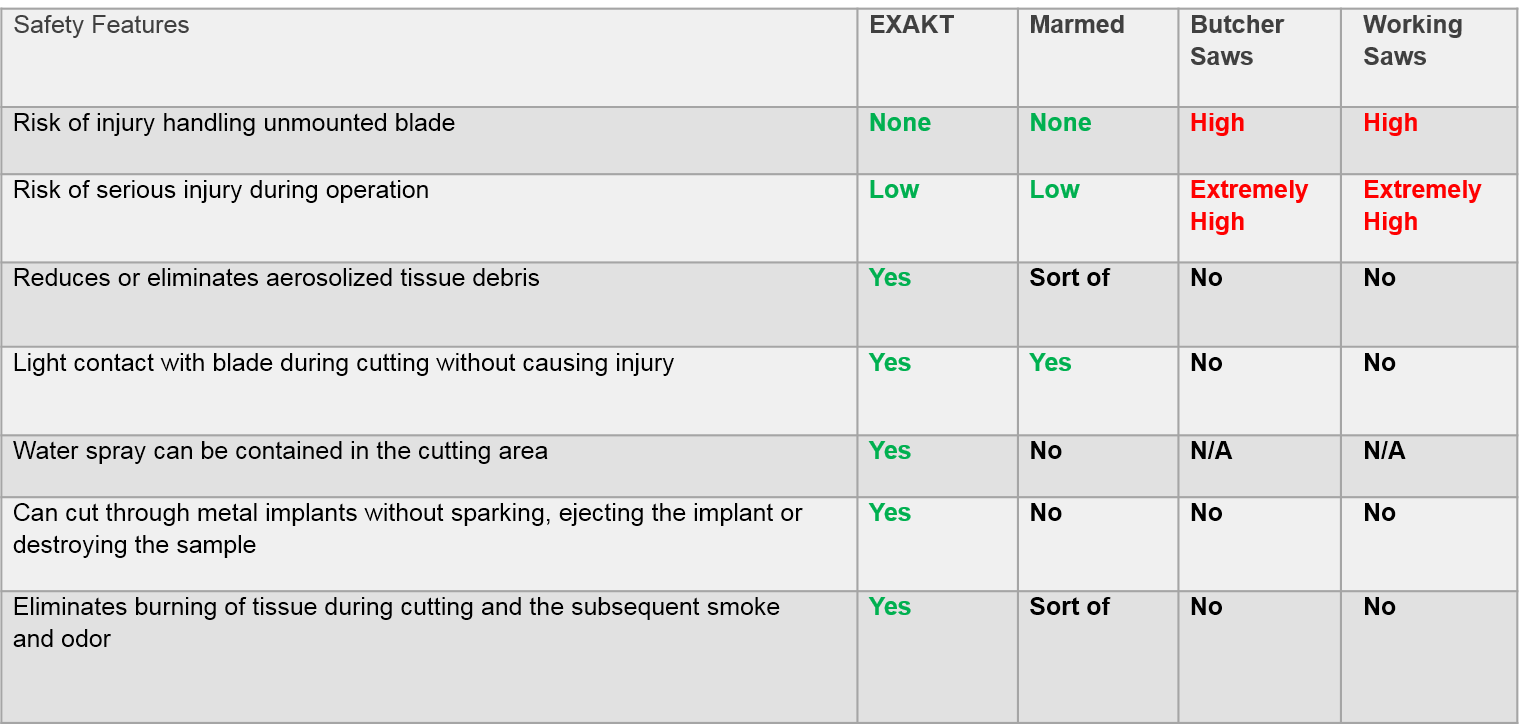

› Safe operation – Minimal risk of the operator being cut

› Coplanar cuts with very tight tolerances

› Flexible and very precise alignment of the samples

› Cutting process for a wide variety of different materials, composites and components

› A variety of options for sample support

Learn more about our cutting and grinding products.

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

Recent Comments