Because precision matters.

Experience – More than 30 years of thin sectioning experience and over 2,800 units in use around the world.

Expertise – Leverage our 30 years of experience for your specific application.

Service – our factory-trained technicians are available to help repair and extend the life of your equipment.

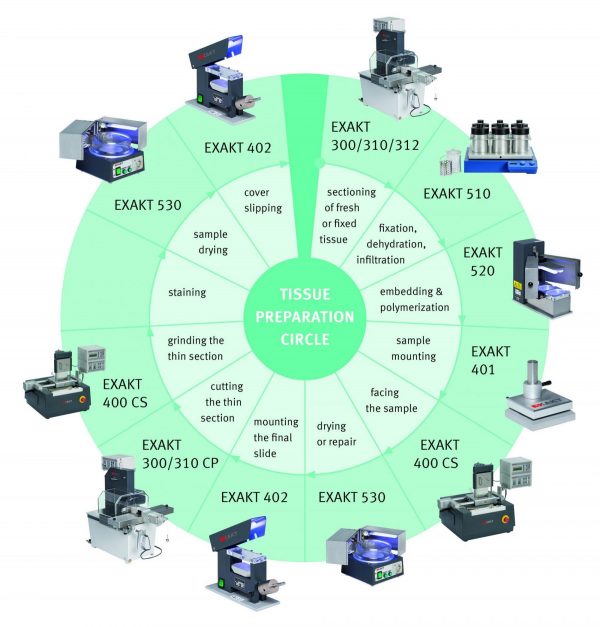

Products – Our products offer the largest variety and flexibility for sample preparation applications.

Precision – nothing says precision and quality like German engineering.

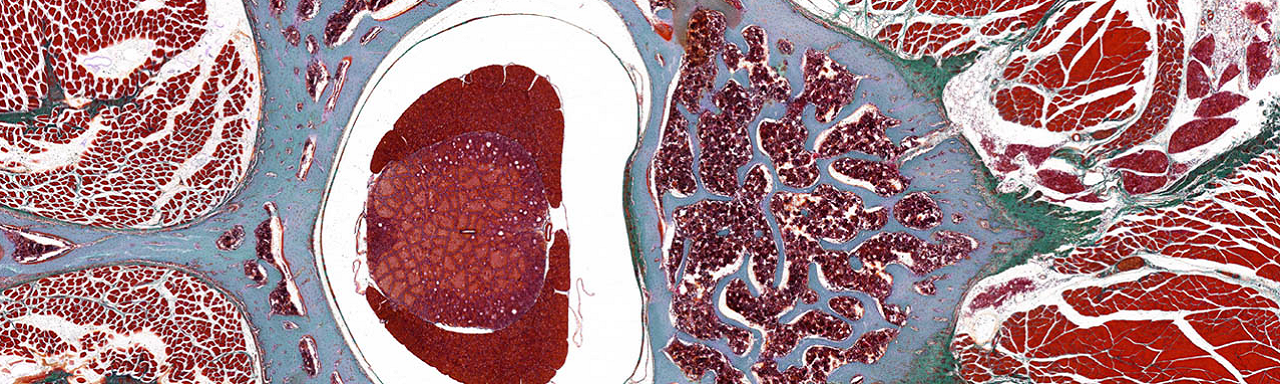

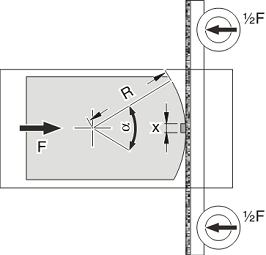

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

EXAKT Cutting and Grinding devices don’t cut with a sharp sawtooth blade, but cut and grind with minimal thermal and mechanical stress on the sample. The EXAKT CP (Contact Point) process ensures pinpoint application of energy. Even in complex components with materials of different hardnesses, the cut is guided precisely while the sample surface quality is left unimpaired.

Recent Comments