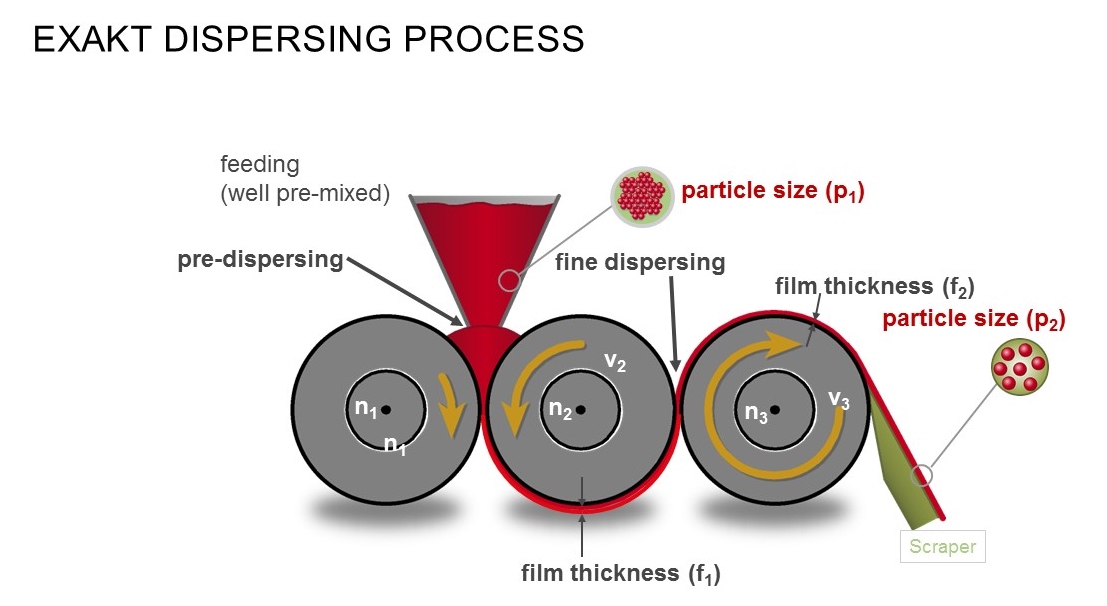

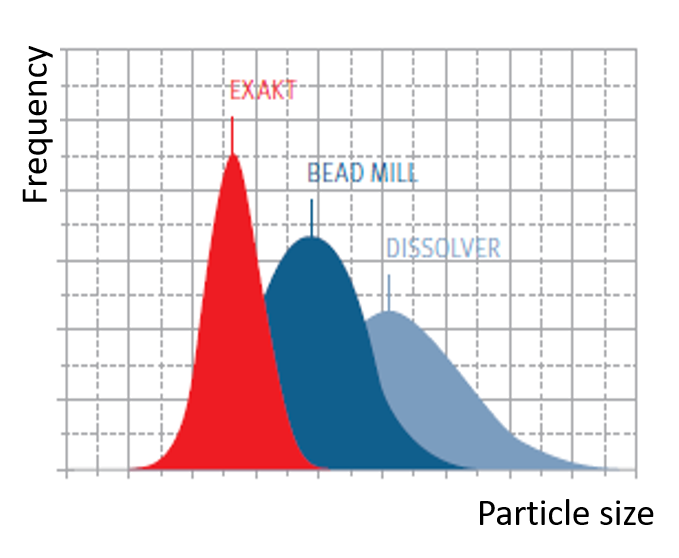

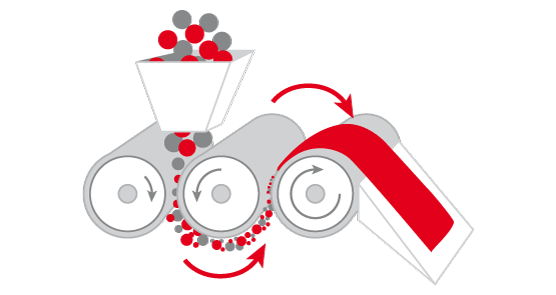

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include:

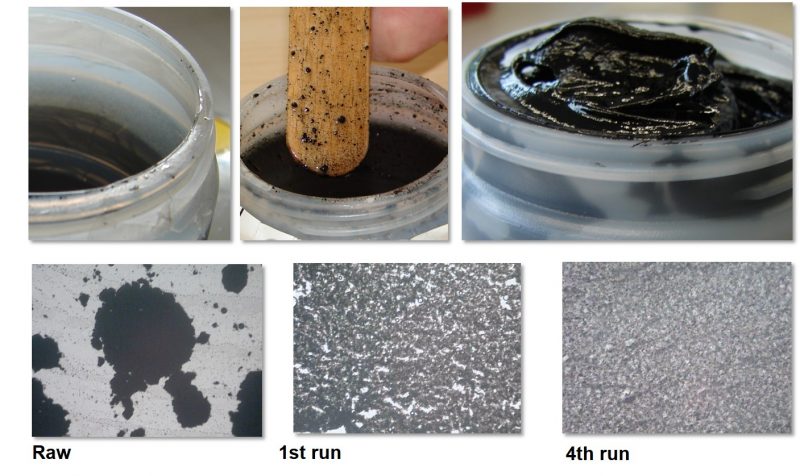

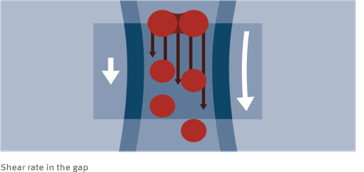

- Disperse the difficult – tangled CNT, especially in viscous pastes such as Epoxy and Silicone.

- Exfoliate graphite-based materials without destroying the plate-like structure.

- Control the level of dispersion.

EXAKT’s electronic models (80E Plus, and 120E) give the most precise control and repeatability.

Whether it’s for research or production, learn more by calling or emailing our three roll mill experts.

800-866-7172 | info@exaktusa.com

Recent Comments