Receive a $200 Visa gift card with the purchase of each Classic 50 ointment mill.

Simply contact one of our distributors to place your order. Ends December 28th, 2017.

Receive a $200 Visa gift card with the purchase of each Classic 50 ointment mill.

Simply contact one of our distributors to place your order. Ends December 28th, 2017.

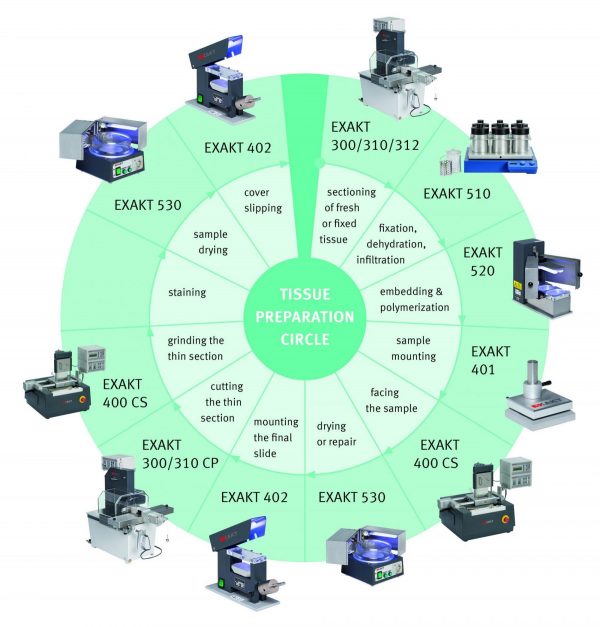

Don’t take chances when handling rare or unique samples. Mistakes in the preparation process delay your work and can provide false results. That’s a risk you shouldn’t take. Trust the decades of experience with globally tried-and-tested thin section cutting technology from EXAKT. We guide you through the sample preparation process, which helps your unique research results.

For more information call 800-866-7172 or send us an email at info@exaktusa.com

Diamond Band – Special characteristics:

Diamond Band – Special characteristics:

Distortion-free / corrosion-free stainless steel

Single diamond layer, nickel embedded

Different band thicknesses and grain sizes

Minimized kerf-loss

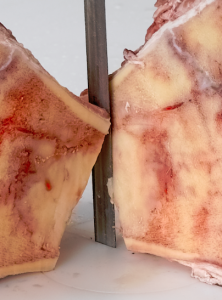

The EXAKT 312 Diamond Band Saw was developed to meet the special requirements of pathology and anatomy (human and

veterinary) medicine. With the EXAKT 312, even the smallest cuts down to about 1 mm can be made freehand with almost no risk of cuts to the operator. Whether it’s soft tissue, bones or implants in the bone-tissue composite, it can all be cut effortlessly and quickly. Not

only this, but it does it with a cut surface quality surpassing every other process available. An initial assessment of the cut can generally be made right away. Outfitted with a variety of different options, the EXAKT 312 can be adapted to individual handling and operating comfort needs.

The EXAKT 312 is very easy to operate and clean. Band changes can be made without tools or adjustment. The stainless-steel housing is consistently designed for good water and tissue drainage. For thorough cleaning and disinfection, modules can be quickly removed without the use of tools.

The EXAKT 312 Diamond Band Saw doesn’t cut, it grinds very precisely. This is the reason for the outstanding surface quality

of the cut surface. Complete preservation of the sample with a surface free of artifacts, micro-fractures and breakouts enables

immediate inspection and assessment of the sample. Even the cell information of very different tissue densities remains

intact. Since the cutting band grinds rather than cuts, there is no immediate risk of injury to the operator in case of inadvertent

contact, which is a first in work safety! Tricky samples with implants, in particular, can be precisely

and safely processed. Guiding the cut is easy and precise, and the process is clean and quiet. Water cooling also reduces dust

development and ensures that the sample doesn’t overheat.

› Superior cut surface quality

› Maximum working safety enables cuts down to 1 mm

› Integrated water cooling prevents overheating of the sample, reduces dust development and keeps the cutting band cleaner

› Cutting band changed without tools or readjustment

› Fast and easy cleaning through the tool-less removal of contaminated modules

› Reliable and time-tested – Hundreds of systems are already in use around the world

When it comes to color brilliance, color effects and high color intensity, EXAKT Three Roll Mills offer significant advantages. For example, the primary particles are not damaged during the processing of metallic and effect pigments. Optimal process control and reproducible quality are a matter of course with EXAKT Three Roll Mills. They satisfy the strictest guidelines for quality assurance and are therefore GMP and ISO auditable. Major companies and brands benefit from EXAKT Three Roll Mills in the production of lipsticks, eyeliners, foundations and nail polishes.

Learn more: https://exaktusa.com/dispersion-equipment/.

For everyday cleaning between formulations, alcohol and a soft cloth or paper towel are the best things to

use. Do NOT spray the alcohol on the rollers or pour the alcohol into the gap when the machine is

running. Put the alcohol on a paper towel or cloth and hold it against the roller tightly while you turn the

roller with the hand wheel.**

When you start to get a build up, you can use an abrasive to clean the rollers. You don’t want to do it too

often because it will remove some of the porcelain over time. Everyone has their favorite product so I’m

going to tell you about several of them.

1. Do not use Ajax or Comet cleansers (even SoftScrub). They have bluing crystals that can leave

blue dye on the roller. If you can find a form of SoftScrub that is made of completely white

powder this will be fine. I personally use Bon Ami cleanser. You can find this in the grocery store

with the other cleansers. I make a slurry of it with either water or Goo-Gone (a citrus based liquid

that cuts oils) and I put it on the tip of a sponge and gently scour the rollers. Other people use

baking soda in a light oil to do the same thing. It is possible to put some of these slurries or Soft

Scrubs in the back gap and run the mill. One or two passes are fine, but if you run it a lot you will

create larger pores in the porcelain.

2. There is a product called Fast Orange Hand Cleaner. You can find it at Wal-Mart, Sam’s,

Home Depot, auto parts stores etc. It’s a pumice based hand cleaner that is the consistency of

jelly. You can use this as well. When we have a particularly badly stained roller, we will run it

through the mill with the gaps slightly open. One pass usually takes off any stain or congealed

product. Do NOT use this for more than one pass. The pumice is much more abrasive than the

cleanser or baking soda. You can put a little on a damp sponge and spot clean with it gently.

Once you’ve done any of these, you should thoroughly clean the rollers with soap and water and then

remove that residue with alcohol before running a new product.

** Many pharmacies are running back-to-back ointments and need to clean their mills quickly.

So rather than turn the rollers with the hand wheel they leave the machine running while they

clean. Not only is this unsafe for the technician, but it makes it easy to get the cleaning cloth

caught in the gap. When this happens, there is a risk not only to the technician but to the

machine and its precision. It is possible to bend the shafts of the rollers if something too big

is pulled in and the repair/replacement can be costly.

When conventional cutting processes reach their limits or the requirements on surface quality of the interface are very high, EXAKT diamond band saws like the 300, 310 (CL & CP), and 311 series are the solution to your problems.

EXAKT diamond band saws are used on a daily basis around the world for thin sectioning. Applications from medicine and industry include:

Precision, consistency, versatility, and safety are the main feature of our thin section technology and our promise of executing demanding cutting tasks in research, production, quality assurance, and damage analysis in a practical way.

To learn more, call 800-866-7172, or info@exaktusa.com.[/vc_column_text][/vc_column][/vc_row]

The large working table and splash guard make your work easier and more efficient. Learn more: http://www.pathologysaw.com

Recent Comments