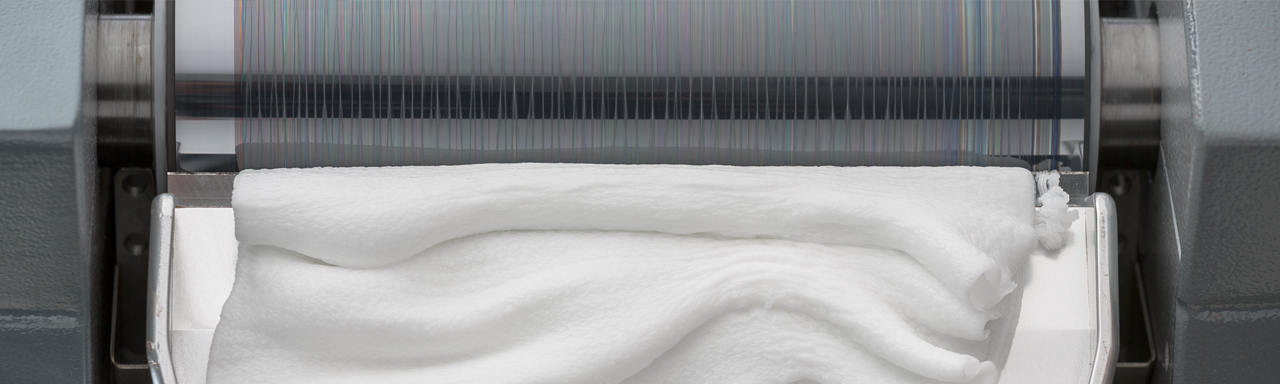

The latest generation of the EXAK T 120S Plus Three Roll Mill technology features state-of-the-art safety functionality, optimum operation and precise setting of the gap.

The EXAT 120S Plus offers continuously good results at particle fineness down to 5 μm. When the increased volume and simple handling are required, the120S-450 is the best choice. The process conditions are very easily adapted to the product to be processed. A continuously adjustable processing speed, excellent temperature control, and alternative roller materials provide the best prerequisites for a multitude of material requirements. The compact desktop model is found everywhere in production. The solid processing of the machine provides absolutely parallel, manually adjusted roller gaps for uniform processing.

- Easily monitor speed, temperature, production timer, and power consumption

on the color display - Roller gap to 5 μm

- Precise setting of the roller gap, no dry running possible

- Up to 27 l/h throughput with a gap width of 10 μm

- Ceramic (aluminum oxide, silicon carbide) or hardened chrome rollers

- Precise one-hand adjustment, continuous and with scale

- High safety standard

- Separate cleaning and reverse operation mode

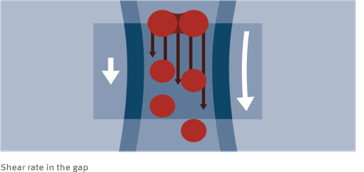

Only the three roll mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones.

- The shear rate between the rollers is the decisive factor for the process.

- This is determined by the roller spacing and the circumferential speed.

- Agglomerates and powder clumps are broken up and homogenized.

- The more controlled the energy input, the more precise the processing.

The new EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control and the choice of ceramic and metallic rollers, the new 80S Plus was designed for processing a wide range of different materials.

This three roll mill works well with both small quantities in the laboratory or larger production quantities. Different working widths and exceptional safety devices ensure ideal working conditions for many products.

- Easily monitor speed, temperature, production timer, and power consumption on the color display

- Adjustable gap range: 5 to 230 μm

- Variable throughput from as little as 10 ml up to 18 l/h at a 10 μm gap

- Covers made of stainless steel, blasted or optional electro-polished

- Roller materials: Chrome, tungsten carbide, aluminum oxide or silicon carbide

- Meets or exceeds safety standards specified in ANSI

The new EXAKT 80S PLUS has higher safety standards, easier operation, and an even more precise adjustment of the gap. With a powerful motor, optional temperature control and the choice of ceramic and metallic rollers, the new 80S Plus was designed for processing a wide range of different materials.

This three roll mill works well with both small quantities in the laboratory or larger production quantities. Different working widths and exceptional safety devices ensure ideal working conditions for many products.

- Easily monitor speed, temperature, production timer, and power consumption on the color display

- Adjustable gap range: 5 to 230 μm

- Variable throughput from as little as 10 ml up to 18 l/h at a 10 μm gap

- Covers made of stainless steel, blasted or optional electro-polished

- Roller materials: Chrome, tungsten carbide, aluminum oxide or silicon carbide

- Meets or exceeds safety standards specified in ANSI

Cosmetic chemists use EXAKT three roll mills to achieve greater color brilliance and fineness in medium to high viscosity substances. EXAKT mills are excellent for breaking open agglomerates and reducing particle sizes to the micron level. Precise, compact, and efficient, EXAKT three roll mills are among the most user-friendly devices in the cosmetic industry. Learn more at EXAKTDispersion.com.

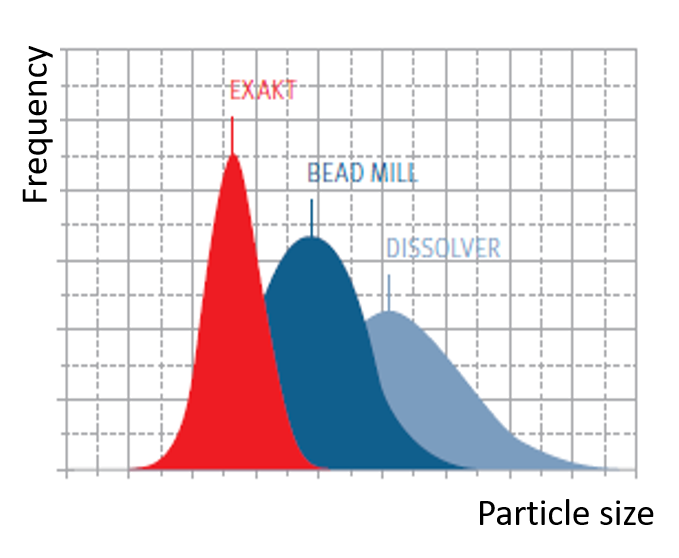

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

- Particle size is smaller.

- Particle size distribution is narrow.

- Ointment stability is better.

- Temperatures do not increase significantly during processing.

- Ointments are softer consistency with lower flow limits

- Three roll mills allow for quality control during processing.

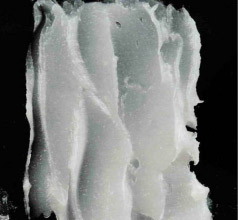

Substance processed with conventional mixing procedure: crystalline substances are still clearly visible.

Substance processed with an EXAKT three roll mill: regular and fine consistency of the substance

LED Lighting

For optimal illumination of the workspace

Mobility Set

Removable castors to move device easily

Water Pistol

For fast cleaning of the entire system.

Add another layer of safety to your mill with this cleaning guard. Only compatible with the EXAKT 50 I. Order by calling 800-866-7172. Or email: EXAKTorders@exaktusa.com.

Recent Comments