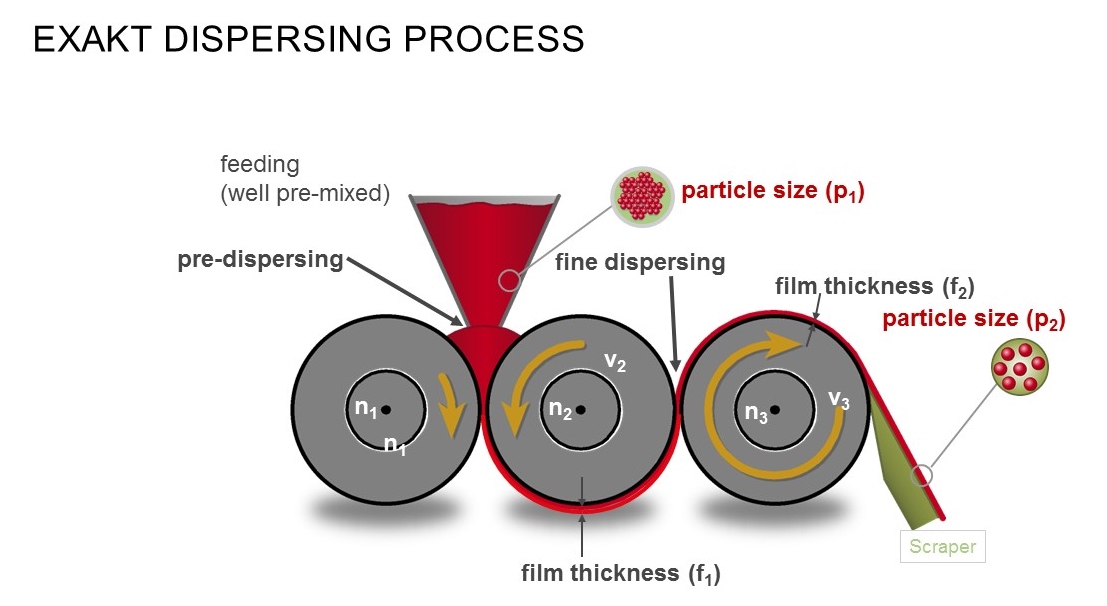

From the food industry to nanotechnology, EXAKT three roll mills are used in a wide variety of industrial and research applications. No matter which paste must be processed, the EXAKT three roll mills can break open all kinds of agglomerates. This creates substances of the greatest fineness and quality.

- Adhesives: conductive, filled, underfills

- Colors: inks, coatings paints

- Cosmetics: lipsticks, eyeliner, makeup

- Dental: gels, pastes, restorative materials

- Electronics: flux, metal or carbon pastes

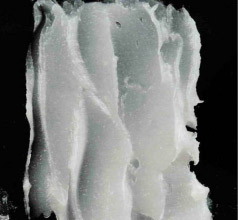

- Grease and lubrication

- Nano Technologies: graphene, CNT, ceramics

Learn more about EXAKT three roll mills.

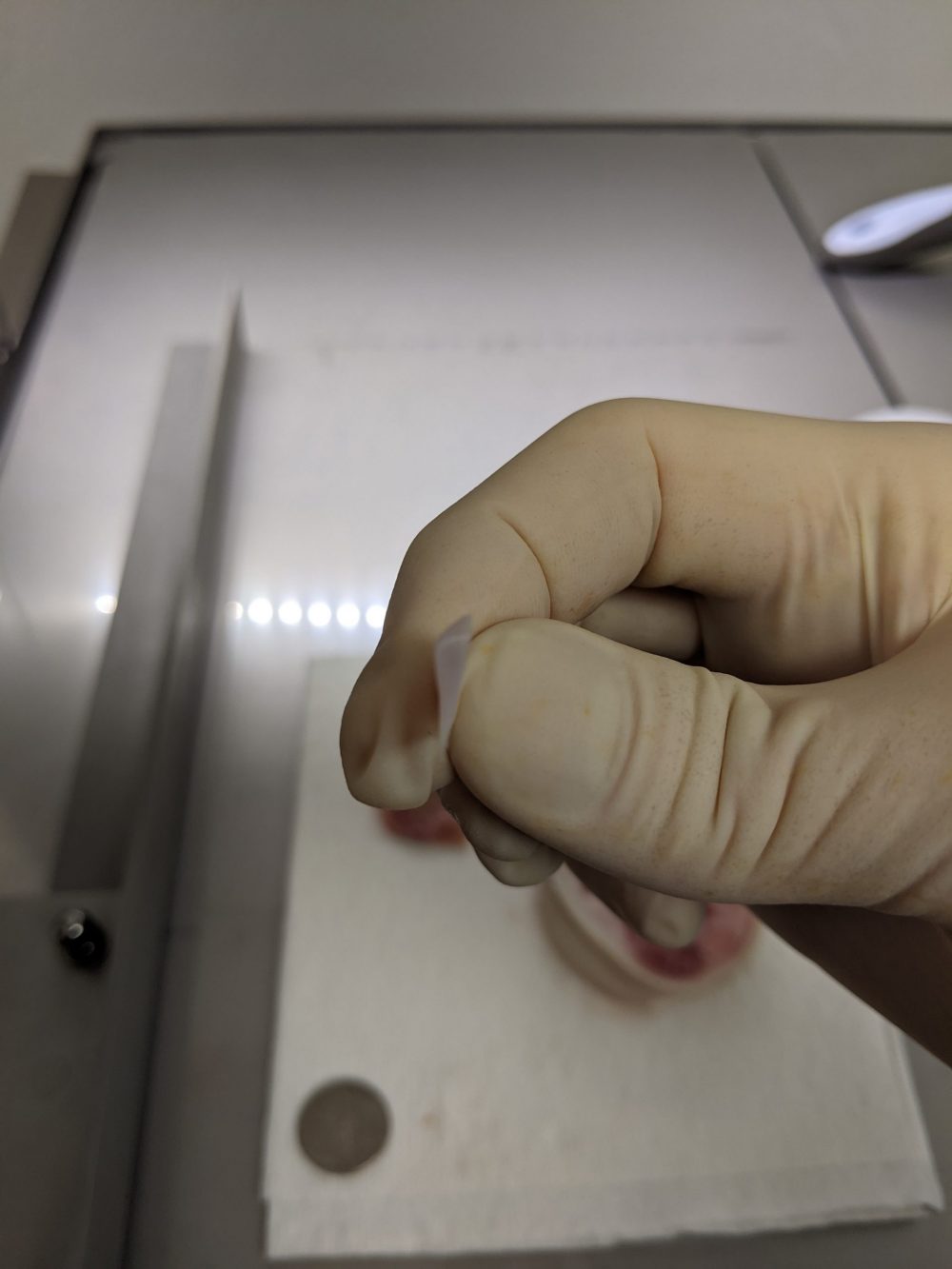

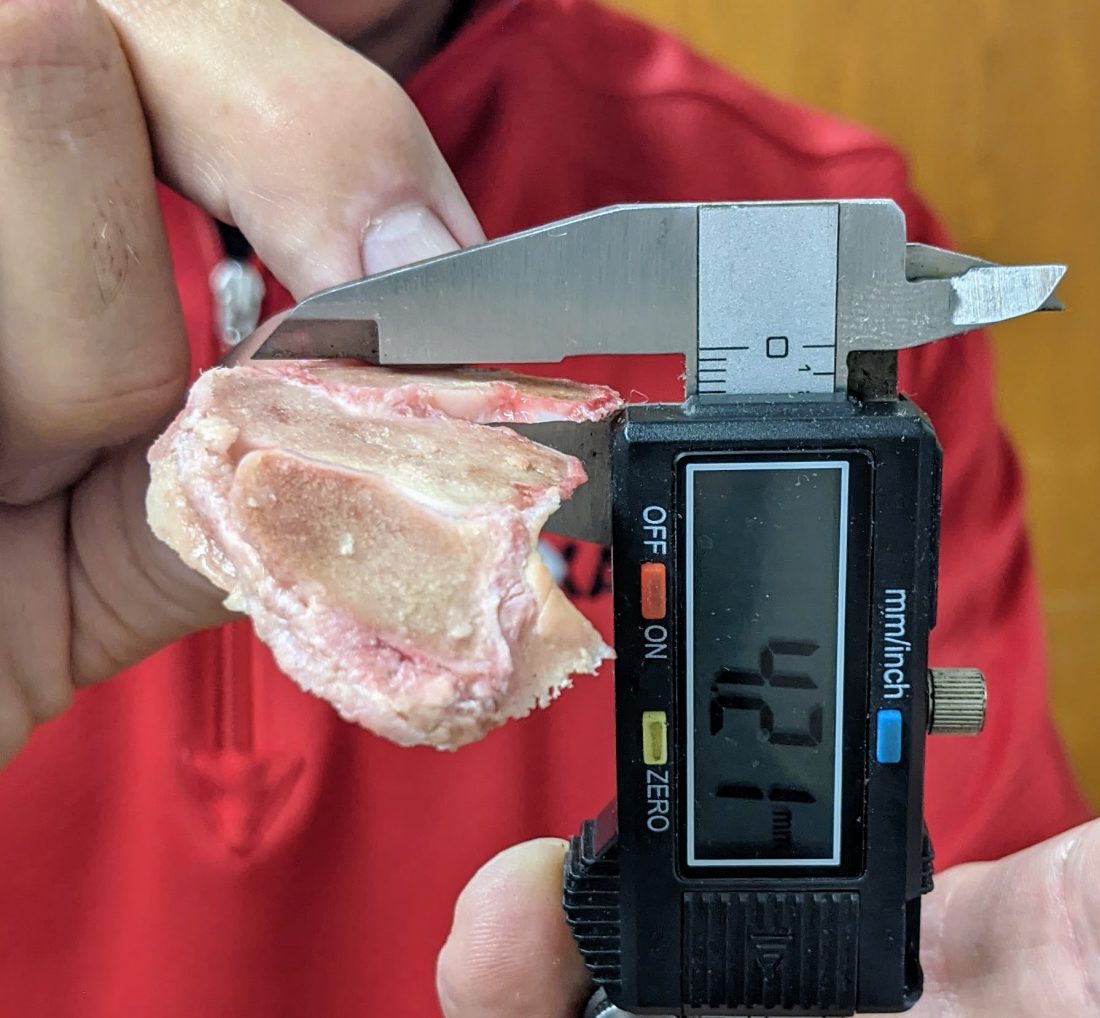

EXAKT’s three roll mills are excellent for grease and lubrication applications.

Recent Comments