EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

EXAKT three ointment mills deliver results that are consistent and reproducible.

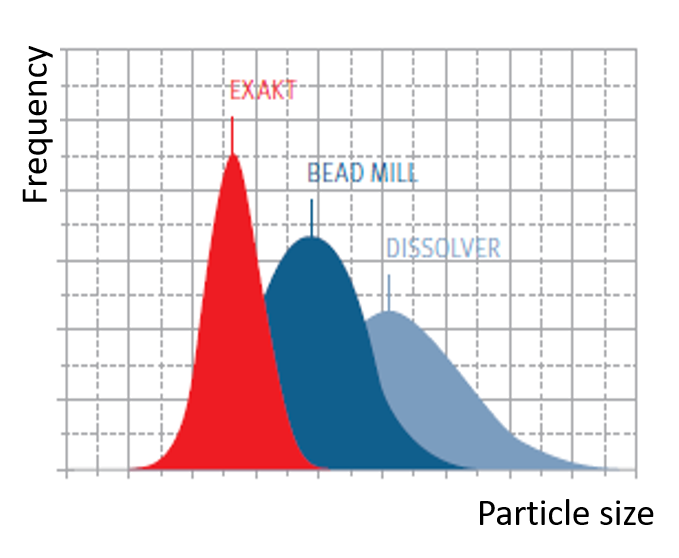

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with three roll mills is better than those processed with electric mixing systems. The study highlighted the following conclusions:

Only the ointment mill used in the dispersing process guarantees that 100% of the product will be passed through both shear zones.

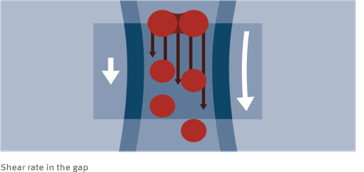

An ointment mill utilizes high shear force to disperse active ingredients, and homogenize viscous materials.

Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other.

The product is pulled through the gaps between the rollers. Active ingredients and powder clumps are broken up and homogenized, which removes grittiness and results in a high-quality topical. This gives your customers a pharmaceutically elegant and effective ointment.

Experience – More than 60 years in milling compounds, more than 45,000 systems installed worldwide.

Expertise – Extensive knowledge of applications with a wide variety of materials.

Service – Factory-trained technicians are available to help repair and extend the life of your equipment.

Products – Machines are made for the customer with the highest precision in manufacturing and assembly. And we have the smallest tolerance ranges in the market.

Precision – Nothing says precision and quality like German engineering.

Problem:

Labs are using equipment originally designed to cut wood, stained glass, and even butchered meat. This has led to poor quality samples and extremely dangerous working conditions.

Solution:

EXAKT’s 312 Pathology Saw was specifically designed for the path lab after years of experience and cooperation with hospitals and universities.

Results:

High-quality gross samples with little or no destruction of the tissue, soft or hard. Designed to be safely operated by the PA or Resident without risk of cutting themselves or breathing in aerosolized bone and tissue matter.

The EXAKT 120E provides higher productivity and more power with the same precision as the 80E Plus. This makes it the ideal equipment for a scale-up when higher production volumes are required. Continuously excellent results for particle fineness down to 1 μm and stable production conditions. This mill has proven its worth wherever maximum reproducibility and control are required. This model is found in laboratory and production environments.

Recent Comments