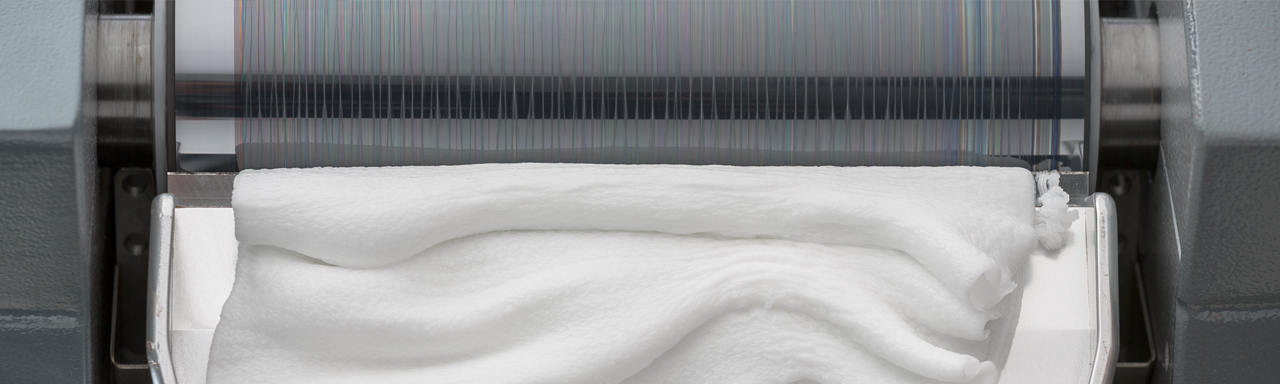

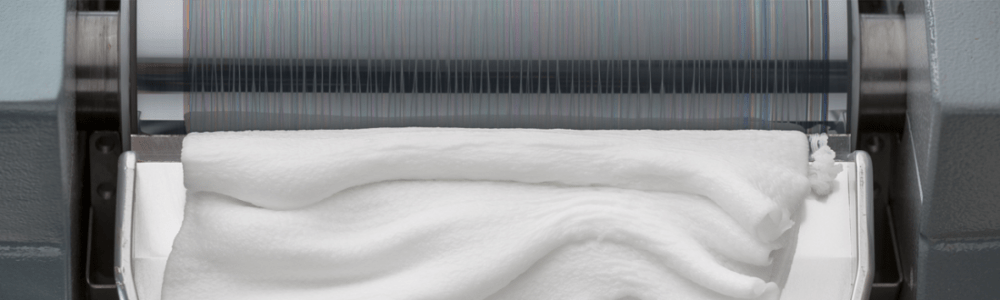

Cosmetic chemists use EXAKT three roll mills to achieve greater color brilliance and fineness in medium to high viscosity substances. EXAKT mills are excellent for breaking open agglomerates and reducing particle sizes to the micron level. Precise, compact, and efficient, EXAKT three roll mills are among the most user-friendly devices in the cosmetic industry. Learn more at EXAKTDispersion.com.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

- Particle size is smaller.

- Particle size distribution is narrow.

- Ointment stability is better.

- Temperatures do not increase significantly during processing.

- Ointments are softer consistency with lower flow limits

- Three roll mills allow for quality control during processing.

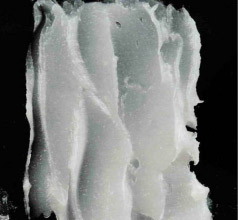

Substance processed with conventional mixing procedure: crystalline substances are still clearly visible.

Substance processed with an EXAKT three roll mill: regular and fine consistency of the substance

Add another layer of safety to your mill with this cleaning guard. Only compatible with the EXAKT 50 I. Order by calling 800-866-7172. Or email: EXAKTorders@exaktusa.com.

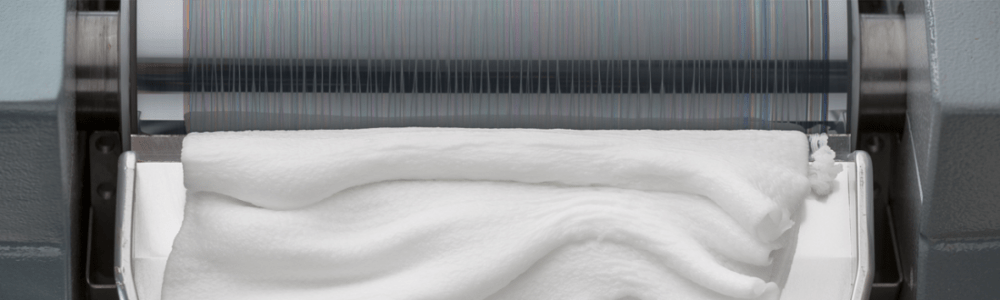

For producing truly elegant preparations of creams, ointments or gels there is no tool more effective or more complete than an ointment mill. And the EXAKT 50 EC+ delivers more control in making that elegant preparation.

HIGHLIGHTS

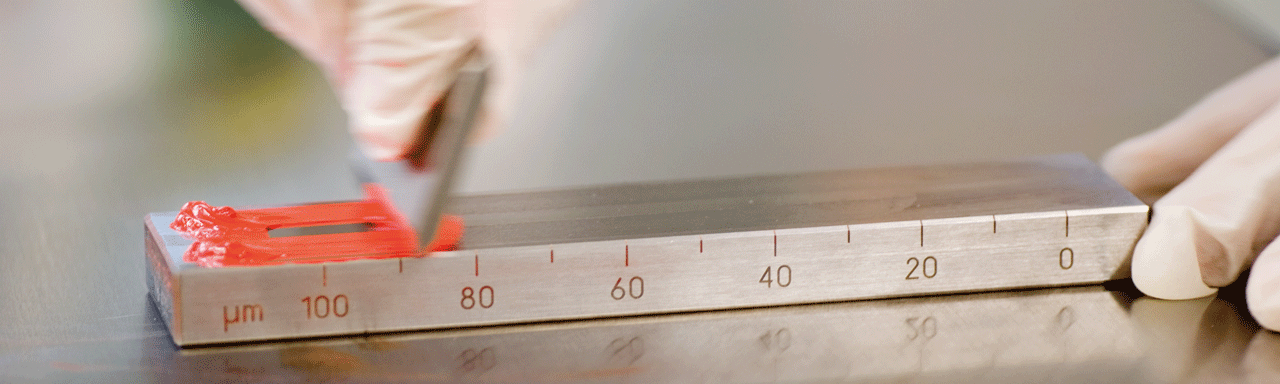

› Roller gap to 10 μm

› Precise setting of the roller gap, no dry running possible

› Up to 5 l/h throughput with a gap width of 10 μm

› Continuously adjustable circumferential speed of the rollers

› Interchangeable roller set

› Ceramic or hardened chrome rollers

› Precise one-hand adjustment, continuous and with scale

› Self-adjusting scraper knife

› Overload protection

.

For optimum results, we offer rollers in different metallic or ceramic materials and surfaces for our three roll mills. Which roller is best suited for your application? Just ask our experts: info@exaktusa.com.

The EXAKT 50 I Three Roll Mill is an especially compact, versatile and easy-to-operate unit for applications where excellent dispersing is essential. Working with separate roller sets is particularly effective in regard to fast cleaning, the avoidance of cross-contamination and downtimes due to changing the product. EXAKT 50 is indispensable for research, development, and training.

- Roller gap to 10 μm

- Precise setting of the roller gap, no dry running possible

- Up to 5 l/h throughput with a gap width of 10 μm

- Continuously adjustable circumferential speed of the rollers

- Interchangeable roller set

- Ceramic or hardened chrome rollers

- Precise one-hand adjustment, continuous and with scale

- Self-adjusting scraper knife

- Overload protection

Chemical engineers use EXAKT three roll mills to improve penetration values and reduce noise in grease and lubrication formulations. Precise, compact, and efficient, these mills are among the most user-friendly devices in the industry. Learn more at EXAKTDispersion.com

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems.

- Particle size is smaller.

- Particle size distribution is narrow.

- Ointment stability is better.

- Temperatures do not increase significantly during processing.

- Ointments are softer consistency with lower flow limits

- Three roll mills allow for quality control during processing.

Substance processed with conventional mixing procedure: crystalline substances are still clearly visible.

Substance processed with an EXAKT three roll mill: regular and fine consistency of the substance

EXAKT three ointment mills deliver results that are consistent and reproducible.

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with three roll mills is better than those processed with electric mixing systems. The study highlighted the following conclusions:

- The particle size is smaller.

- Particle size distribution is narrow.

- Ointment stability is better.

- Temperatures do not increase significantly during processing.

- Ointments are softer consistency with lower flow limits.

- Ointment mills allow for quality control during processing.

EXAKT three roll mills deliver results which are consistent and reproducible.

- Process materials accurately and dependably, including Nano particles

- Narrowest particle distribution

- No separation

- Processing down to 5 ml, virtually loss free

- Minimal cleaning losses

- Durable mills mean low operating costs

Recent Comments